Views: 222 Author: Amanda Publish Time: 2025-09-08 Origin: Site

Content Menu

● What is a Used Mini Excavator?

● Factors Affecting the Price of a Used Mini Excavator

>> Condition and Maintenance History

>> Attachments and Accessories

● Average Price Range for Used Mini Excavators

● Where to Buy Used Mini Excavators

>> Authorized Dealers and Rental Companies

>> Local Classified Ads and Auctions

● How to Inspect a Used Mini Excavator Before Purchase

● Benefits of Buying a Used Mini Excavator

● Maintenance Costs to Expect with a Used Mini Excavator

● Financing Options for Used Mini Excavators

● Frequently Asked Questions (FAQs)

>> 1. How much does a used mini excavator typically cost?

>> 2. What brands are best for used mini excavators?

>> 3. How many hours of use is ideal for a used mini excavator?

>> 4. Can accessories like buckets increase the price of a used mini excavator?

>> 5. Is it better to buy from a dealer or a private seller?

Choosing the right equipment for construction, landscaping, or agricultural projects is essential to maximize efficiency and control costs. When it comes to compact digging tasks, a used mini excavator can be a fantastic investment. However, understanding how much a used mini excavator costs—a question many buyers ask—can be complicated due to various influencing factors.

In this comprehensive guide, we will break down the costs of used mini excavators, explore the factors that affect pricing, and help you make an informed decision whether you are a business or an individual. Let's dive into the details.

A mini excavator is a compact construction machine designed to perform small to medium-sized digging tasks. It is widely used for landscaping, trenching, utility work, and demolition. Mini excavators typically weigh between one and six tons and feature a hydraulic arm, a rotating platform, and tracks that allow them to access tight and uneven spaces.

When buying a used mini excavator, you are purchasing a machine that has been previously owned and operated but is offered at a reduced cost compared to new models. These machines are ideal for smaller projects, urban construction sites, or places with limited access where larger excavators cannot operate efficiently.

Used mini excavators can offer excellent value if properly maintained and sourced from reliable dealers or sellers. They allow businesses to expand fleet capabilities and individuals to complete personal or small business projects economically.

Understanding why prices differ will help you negotiate and find the best deal. Several key factors influence the cost of a used mini excavator:

Popular brands like Caterpillar, Kubota, Bobcat, John Deere, and Takeuchi tend to retain higher resale value. These brands are known for reliability, durability, and strong dealer support. Well-known models may also offer better parts availability and service options, which can influence purchase price and total cost of ownership. Machines from lesser-known or generic brands might be cheaper but can have higher maintenance costs and lower resale appeal.

The depreciation of mini excavators largely depends on their age and total operational hours. Similar to vehicle mileage, the number of hours a machine has worked indicates wear and tear. A newer machine or one with lower hours will usually cost more because it can be expected to last longer and require fewer repairs in the short term.

Mini excavators with fewer than 2,000 hours are often considered to be in “good” condition. Machines with over 5,000 hours are usually approaching the end of their useful life unless they have undergone major rebuilds or refurbishments.

Well-maintained machines with documented service records and proper storage command higher prices. Buyers prefer units with regular oil changes, hydraulic inspections, and track replacements. Visible corrosion, hydraulic leaks, worn-out parts, or engine problems can significantly reduce a machine's value.

A thorough history showing that the previous owner operated and serviced the unit responsibly often means less risk for the buyer and potentially longer machine life.

Mini excavators come in various sizes, ranging approximately from 1 ton to 6 tons. The weight determines the machine's digging power, lift capacity, and general capability. Larger machines in the mini excavator class often cost more due to their greater power and versatility but may require more maintenance.

Smaller models are typically preferred for landscaping and residential tasks while larger models handle heavier-duty jobs like roadwork or small demolition projects.

Attachments add to the total price but improve the machine's versatility. Common attachments for mini excavators include buckets of various sizes and types, hydraulic breakers, augers, grapples, and thumbs.

Machines with well-maintained and included attachments are attractive to buyers who want multi-purpose use out of their investment. However, you should evaluate whether you need these attachments because adding them may increase the initial purchase price.

Prices can vary based on geographic location and market demand. Urban or rapidly developing regions typically have higher demand for construction machinery, thus raising used equipment prices. In rural or less developed areas, prices may be lower due to fewer buyers and less competition.

Shipping or transportation costs may also affect the final price, especially if you purchase from a distant city or import from overseas.

To give you a clearer picture, here is a detailed breakdown of typical prices you can expect for used mini excavators based on size and condition:

Sub-1 ton machines: These are very compact and usually cost between $8,000 and $20,000. They are best suited for extremely tight spaces and small landscaping projects.

1 to 2 ton models: These are popular for urban landscaping, utility, and maintenance work. Prices range from $15,000 to $35,000, depending on condition and attachments.

3 to 4 ton excavators: Known for their versatility and power, these machines typically sell between $20,000 and $50,000. They can handle tougher digging jobs and limited demolition.

5 to 6 ton machines: These are on the upper end of the mini excavator size and can cost between $40,000 and $70,000 when used. Such machines serve heavier construction and excavation tasks.

These price ranges are approximate and may shift with market conditions, brand premiums, and machine availability.

Finding a reliable used mini excavator involves considering several purchasing channels:

Many equipment dealers sell used mini excavators certified through rigorous inspections, sometimes with warranties included. Rental companies also sell their fleet machines routinely, providing options that have been systematically maintained and serviced.

Equipment auction websites, online classifieds, and heavy machinery marketplaces offer a wide variety of used mini excavators at competitive prices. Buyers should exercise caution by carefully verifying seller reputation and equipment condition.

Local auctions and classified sales occasionally feature good deals on used mini excavators. These venues require buyers to inspect machines in person prior to purchase, as returns are rare.

Buying directly from contractors or businesses that are upgrading their equipment can offer cost advantages. However, it is crucial to thoroughly inspect the machine and request maintenance records.

To avoid costly mistakes, conduct a thorough inspection or hire a professional to do it for you. Here are the main points to check:

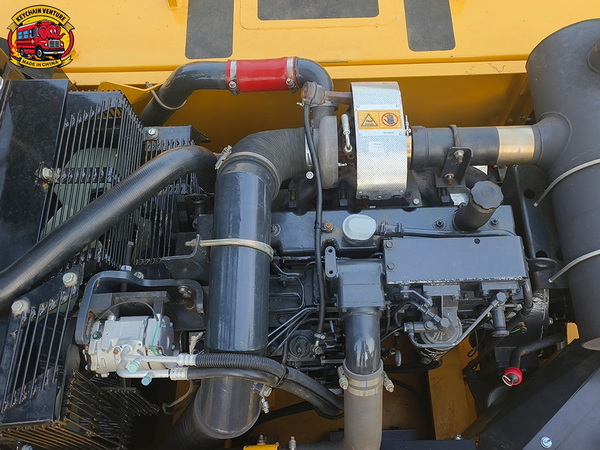

- Engine and Hydraulics: Listen for unusual noises such as knocking, grinding, or excessive exhaust smoke. Check for hydraulic leaks around cylinders, hoses, and pumps.

- Operational Controls: Test all controls, including the swing system, boom/dipper movement, and travel. They should operate smoothly without lag or sticking.

- Undercarriage: Tracks, rollers, sprockets, and idlers should be inspected for wear and damage. Excessive track stretching produces performance issues.

- Attachments: Examine buckets for cracking, dents, or excessive tooth wear. Inspect attachment pins and bushings for wear.

- Fluids: Check engine oil, hydraulic fluid, coolant, and transmission fluid. Dirty or contaminated fluids may indicate neglect.

- Service History: Request service logs, repair records, or inspection reports to verify continuous maintenance.

- Visual Damage: Look for dents, rust, corrosion, and signs of previous accident damage.

- Test Operation: If possible, operate the mini excavator on-site to assess performance.

Purchasing a used mini excavator comes with several advantages:

- Significant Cost Savings: Used machines can be 30%-50% cheaper or more than new models, freeing up capital.

- Slower Depreciation: New machinery depreciates rapidly during the first few years; used machines tend to hold their value better.

- Availability of Equipment: Used machines often come with attachments and accessories that are otherwise costly when purchased new.

- Faster Return on Investment: Lower purchase price reduces the time to recoup investment when the equipment is deployed on projects.

- Flexibility: Buying used allows businesses and contractors to scale operations without large upfront costs.

Owning a mini excavator requires budget allocation for ongoing maintenance. Typical costs include:

- Routine Servicing: Oil changes, filter replacements, hydraulic fluid changes, and lubrication—essential to avoid premature failures.

- Track and Undercarriage Repairs: Tracks wear over time and may need replacing. Rollers or sprockets might require servicing.

- Hydraulic System Upkeep: Hoses, seals, and cylinders require inspection and repair to prevent leaks.

- Engine Maintenance: Servicing injectors, turbochargers, and engine components as required.

- Attachment Maintenance: Repairs to buckets, thumbs, or breakers depending on use.

Proper maintenance prevents costly breakdowns and prolongs machine life.

If the upfront cost of a used mini excavator is a concern, financing options may be available:

- Equipment Loans: Commercial loans designed specifically for purchasing construction equipment. Terms vary by lender.

- Leasing Options: Leasing allows usage for a fixed period with options to buy at lease end.

- Dealer Financing: Many dealers offer in-house financing solutions with competitive rates.

Before selecting financing, compare interest rates, down payment requirements, loan terms, and hidden fees to ensure affordability.

Investing in a used mini excavator can dramatically enhance your project capabilities without breaking your budget. Prices vary due to factors such as brand, age, condition, and size, but with thorough research and careful inspection, you can find a reliable machine that fits your needs and budget.

By understanding the market and what influences used mini excavator pricing, you will be empowered to make a purchase that delivers long-term value. Whether for commercial use or private projects, selecting the right used mini excavator is a smart investment. Proper maintenance and sensible financing further increase the benefits of owning a used mini excavator, helping you to get the best return on your expenditure.

Prices for used mini excavators generally range from $8,000 to $70,000 depending on the machine's size, age, condition, and included attachments.

Kubota, Caterpillar, Bobcat, Takeuchi, and John Deere are among the top brands, known for durability, availability of parts, and strong resale value.

Machines with fewer than 2,000 hours of operation are often preferred because they are less worn and usually require less immediate maintenance.

Yes, attachments such as buckets, breakers, augers, and thumbs can add to the purchase price but also improve the machine's versatility and utility.

Authorized dealers generally provide machines with warranties and service history, offering greater buyer protection. Private sellers can sometimes offer lower prices but require thorough inspections to avoid risks.