Views: 222 Author: Amanda Publish Time: 2025-11-22 Origin: Site

Content Menu

● What Is an Excavator Hammer?

● Core Components and Working Principle

>> How It Works

● Matching a Hammer to a Used Excavator

>> Hydraulic Flow and Pressure

● Preparing Your Used Excavator for Hammer Work

● Attaching the Excavator Hammer

● Operating Techniques for Efficient Hammering

>> Strike Duration and Repositioning

>> Using Power and Frequency Controls

● Protecting the Machine During Operation

>> Managing Backpressure and Heat

● Daily and Periodic Maintenance

● Optimizing Productivity with a Used Excavator

● Environmental and Cost Benefits of Reusing Equipment

● FAQ

>> What size hammer should I use on my Used Excavator?

>> How do I prevent damage to a Used Excavator while hammering?

>> How often should I grease the hammer tool on a Used Excavator?

>> Why is my excavator hammer losing power on a Used Excavator?

>> Can a Used Excavator with a hammer work efficiently in very hard rock?

Operating an excavator hammer correctly is essential for efficient breaking of concrete, rock, and other hard materials, especially when paired with a reliable Used Excavator. The following complete guide explains the working principles, setup, operation, maintenance, safety, and optimization tips to help operators get the most from their machines.

An excavator hammer (hydraulic breaker) is a powerful attachment driven by the excavator's hydraulic system to deliver repeated high-energy blows through a steel tool, typically a chisel or moil point. When matched properly with a Used Excavator, it enables fast demolition, trenching, quarry work, and secondary breaking on construction and mining sites.[5]

The hammer transforms hydraulic pressure and flow into linear impact energy, allowing a Used Excavator to perform tasks that would otherwise require larger dedicated machines. This makes it a cost-effective and flexible solution for contractors who operate mixed or aging fleets.[5]

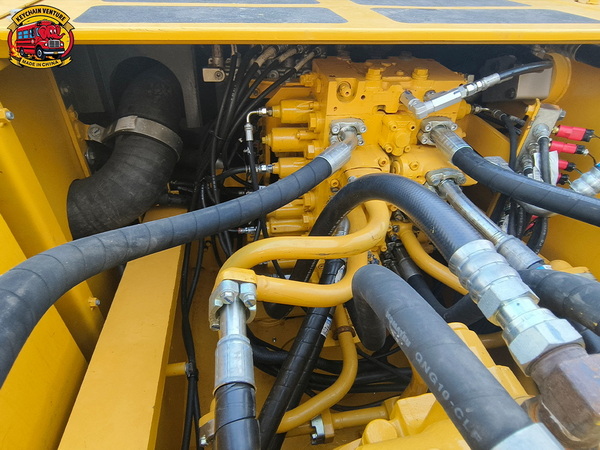

Key components of a typical excavator hammer include:[7][5]

- Hammer body housing and tie-bolts

- Hydraulic piston

- Valve system and internal passages

- Tool bushings and chisel

- Accumulator or damping system (on many models)

The hammer body supports and protects the internal system, while the piston moves at high speed to strike the tool and transfer energy into the material.[5]

Hydraulic hammers operate in a cycle of pressurization, impact, and return stroke:[5]

1. Hydraulic fluid under pressure enters the hammer and drives the piston upward.

2. Valve timing then directs fluid so the piston is forced downward at speed.

3. The piston impacts the tool shank, sending a shock wave into the rock or concrete.

4. The piston returns and repeats the cycle many times per minute.

On a Used Excavator, overall hammer performance depends strongly on the carrier's hydraulic pressure and flow rate, which must be within the breaker's specified range.[5]

Proper sizing and matching protect both hammer and carrier while maximizing productivity.[3][8]

Hydraulic hammers are sized to the excavator's operating weight. As a general guideline:[3]

- Mini excavators (under about 7 tons) use compact hammers in the 60–400 kg class.

- Medium excavators (around 7–20 tons) use 400–1200 kg hammers.

- Large excavators (20–80 tons or more) use heavy hammers from about 1200–6000 kg.

Using an oversized hammer on a smaller Used Excavator can cause instability and structural stress, while undersizing reduces breaking efficiency.[8][3]

Each hammer requires a specific hydraulic flow range (liters per minute) and working pressure to achieve its rated impact energy and blows per minute.[8][5]

- Too little flow or pressure leads to slow, weak blows.

- Excessive pressure or uncontrolled flow risks overheating, seal damage, and early failure.

When pairing a hammer with a Used Excavator, always cross-check the excavator's auxiliary circuit capabilities against the hammer's technical data.[3][5]

Before beginning hammering operations, conduct a full walk-around inspection:

- Check hydraulic hoses and couplers for cracks, abrasion, or leaks.

- Inspect the hammer body for visible deformation or missing hardware.

- Confirm that the chisel is straight, not excessively worn, and properly secured.

- Verify hydraulic oil level and look for signs of contamination or foaming.

Used Excavators may have older hoses and fittings, so any sign of aging or leakage should be addressed before heavy hammer use.

A well-prepared jobsite protects the machine and operator:

- Establish exclusion zones to keep personnel clear of flying debris.

- Ensure the excavator can operate on firm, level ground.

- Plan access routes for moving broken material away to avoid rehandling.

- Consider dust suppression methods when hammering concrete or rock in confined areas.

Correct attachment is crucial to safe and efficient operation.

1. Park and secure the Used Excavator

Lower the boom, set the parking brake, and relieve hydraulic pressure.

2. Install the mounting bracket or quick coupler

Align the hammer's mounting pins with the excavator's linkage or coupler, using the correct pins and bushings specified for the carrier.

3. Connect hydraulic hoses

Clean quick couplers to prevent contamination and connect supply and return lines according to flow direction labels.[5]

4. Check for leaks under low pressure

Start the machine and activate the auxiliary circuit briefly at reduced throttle to confirm there are no leaks.

5. Verify tool movement

Gently actuate the hammer function to ensure the tool moves freely and without abnormal noises.

For Used Excavators equipped with several auxiliary modes, select the one calibrated for breaker use to achieve the proper flow and avoid overloading.[5]

Proper operating technique has a large impact on productivity, fuel use, and component life.

- Keep the chisel as close to perpendicular to the surface as possible.

- Avoid side-loading by not prying or using the hammer as a lever.

- Ensure firm contact between tool and material before striking.

Working at a steep angle or using the hammer to push or lift materials can damage the tool bushings and the boom of a Used Excavator.

Continuous hammering in one spot for too long heats components and wastes energy.[5]

- Limit each burst of hammering to about 15–20 seconds when the material is not cracking.

- If no visible progress is made, stop, change the tool position slightly, and strike again.

- Allow brief pauses between cycles to cool the system.

Effective operators learn to “listen” to the hammer and watch the material, stopping as soon as cracking begins to propagate so as not to over-hammer the same area.

Many modern hammers allow some adjustment of blow frequency and energy.[5]

- Higher frequency with lower individual energy suits softer or thin materials.

- Lower frequency with higher energy is better for large or hard rock.

On a Used Excavator, variations in pump response or older control valves can affect these settings, so operators should test different modes and record which settings work best for each job.

Hydraulic backpressure and heat buildup are common causes of premature hammer and excavator wear.[5]

- Keep the excavator's cooling system clean and functional.

- Monitor hydraulic oil temperature; if it rises abnormally, reduce duty cycle.

- Ensure return lines and filters are correctly rated for hammer flow.

Older Used Excavators are more prone to marginal cooling capacity, so they benefit from shorter operating cycles and more frequent rest periods.

Blank firing occurs when the hammer is activated without the tool firmly pressed against the material.[5]

- Always ensure solid contact before engaging the hammer function.

- Do not continue striking after material breaks away under the tool.

Repeated blank firing increases stress on internal components and shortens hammer life, especially on units mounted on high-hour Used Excavators.

Reliable hammer performance requires consistent maintenance of both the hammer and the Used Excavator.

- Grease the tool bushings at intervals recommended by the manufacturer, often every 2–4 operating hours.

- Inspect hoses and couplers for leaks or damage and clean any accumulated dirt.

- Check chisel wear length and rotate or replace as needed to maintain proper working height.

- Inspect brackets and mounting pins for excessive play.

Lubrication is particularly important for hammers working with Used Excavators, as existing play or wear in the linkage can transfer additional loads to the tool bushings.

- Sample hydraulic oil for contamination indicators like metal particles or milky appearance.

- Verify that operating pressure and flow still meet hammer specifications using service gauges.

- Inspect internal components such as bushings, tool retainers, and seal carriers as recommended by the hammer manufacturer.[5]

Documenting these checks is especially valuable when operating a Used Excavator, providing a history that helps predict failures before they occur.

Different tool shapes are suited to different jobs, and the correct choice helps a Used Excavator perform more efficiently.[9][5]

Common tool types include:

- Moil point – General-purpose breaking of rock and concrete with focused impact.

- Chisel – Better control for directional breaking, such as in trenching or cutting along a line.

- Blunt tool – Effective for secondary breaking of large boulders or slabs through compression.

Matching tool geometry to the material and application improves penetration and reduces time spent on each task.[5]

When properly set up, a Used Excavator can work nearly as effectively as a new unit with a modern hammer.

Strategies to maximize output:

- Use the correct hammer size and tool type for each project.[3][5]

- Train operators on best practices for positioning, strike timing, and load management.

- Plan work so the excavator minimizes idle travel and repositioning between breaks.

- Combine hammer use with attachments like buckets or grapples on other machines to remove broken material promptly.

By standardizing procedures and documenting successful settings for specific materials, fleets that include Used Excavators can achieve consistent, repeatable performance.

Operating a Used Excavator with a high-quality hammer supports both cost control and sustainability. Extending the life of heavy machinery reduces the need for new manufacturing and associated emissions. When combined with efficient hammer operation—using just enough energy and avoiding wasteful practices—contractors can lower fuel consumption and operating expenses while still meeting project schedules.[5]

Using an excavator hammer efficiently requires proper matching of hammer and carrier, correct attachment, disciplined operating technique, and consistent maintenance. When all of these factors are in place, a Used Excavator can deliver powerful, reliable breaking performance comparable to many new machines. By understanding how the hammer converts hydraulic energy into impact, choosing the right tool and settings for the job, and protecting both hammer and excavator from avoidable stress, operators can achieve high productivity, reduced downtime, and longer service life. This combination of technical knowledge and good habits turns a Used Excavator with an excavator hammer into a highly versatile and profitable asset on any jobsite.

Choose a hammer whose weight matches your excavator's operating weight class and whose hydraulic flow and pressure requirements fall within the carrier's auxiliary circuit capabilities. Oversized hammers can destabilize the machine, while undersized units reduce breaking efficiency and increase cycle time.[8][3]

Keep the tool perpendicular to the work surface, avoid prying with the hammer, and limit each hammering burst when material is not breaking to short intervals. Regularly monitor hydraulic temperature and check for leaks or abnormal vibrations to catch issues early.[5]

Most hammer manufacturers recommend greasing the tool bushings every few hours of continuous operation, or more frequently in dusty or abrasive conditions. Consistent lubrication is even more important on Used Excavators, where existing wear in pins and bushings can transfer extra loads to the hammer.[5]

Loss of power can be caused by insufficient hydraulic pressure or flow, worn internal seals, or clogged filters and valves. Verifying system pressure, inspecting oil condition, and checking for obstructions in the hydraulic circuit are key first steps in diagnosing the issue.[5]

Yes, provided the hammer is correctly sized, hydraulic settings are within specification, and the operator uses proper techniques like short, focused strikes and correct tool positioning. In very hard or thick material, lower frequency with higher impact energy, as well as using an appropriate chisel or blunt tool, will improve penetration.[3][5]

[1](https://gorillahammers.com/hydraulic-hammer-breaker-size-guide/)

[2](https://rhinox-group.us/blogs/guides-and-tips/guide-to-excavator-hydraulic-hammers)

[3](https://www.huilianmachine.com/hydraulic-hammer-breaker-sizing-guide-expert-tips-selection-huilian.html)

[4](https://www.npkce.com/wp-content/uploads/2025/05/H050-9610C-E208-E225-Hyd-Ham-Operators-Manual-12-20.pdf)

[5](https://hawkexcavator.com/hydraulic-hammers-for-excavators/)

[6](https://s7d2.scene7.com/is/content/Caterpillar/C10501115)

[7](https://www.beilite.com/en/blog/info_itemid_13497.html)

[8](https://www.dhstructure.com/how-to-choose-a-excavator-breaker-hammer/)

[9](https://www.cat.com/en_US/articles/for-owners/how-to-choose-a-hydraulic-hammer-for-your-applications.html)

[10](https://deepkron.com/blog/hydraulic-breaker-hammer-definition-key-features-guide/)

Field Visit To DR Congo – Products in Action, Friendships in Progress

Treat Your Team to the Perfect Ending: A Cultural Day & Rejuvenating Massage

Just received this absolutely gorgeous bouquet specially ordered by our lovely customer!

Truly inspiring conversations today with our highly insightful client!

Today, we visited the bus company together with our client. It was really wonderful!

A Milestone Moment: Custom Buses Successfully Shipped, Setting Course for New Horizons

Forging Stronger Ties: Welcoming Key African Partners to Chongqing for Transport Collaboration