Views: 222 Author: Amanda Publish Time: 2025-09-19 Origin: Site

Content Menu

● Introduction to Mini Excavators

● Getting Started: Pre-Operation Checklist

● Operating the Mini Excavator

● Working with a Used Excavator

● Additional Attachments and Their Uses

● Safety Precautions When Using Mini Excavators

● Routine Maintenance Tips for Longevity

● FAQ

>> 1. What is the benefit of choosing a used excavator over a new one?

>> 2. How often should I perform maintenance on a mini excavator?

>> 3. Can I operate a mini excavator without prior experience?

>> 4. What are common signs of wear in a used excavator?

>> 5. Is video training effective for learning mini excavator operation?

Operating a mini excavator efficiently and safely is vital for construction professionals, landscapers, and contractors who want to maximize productivity on job sites. This comprehensive guide will walk you through how to use a mini excavator, supported by detailed video demonstrations, highlighting key operational tips, safety measures, and maintenance practices. The article is tailored for both beginners and experienced operators, with an emphasis on the role of used excavator models, a popular choice for cost-conscious buyers and operators seeking reliable performance.

Mini excavators are compact, versatile construction machines designed to perform digging, trenching, demolition, and material handling tasks in confined spaces. Unlike larger excavators, they offer greater maneuverability and ease of transport, making them ideal for urban construction, landscaping, and utility projects. When choosing a mini excavator, many opt for a used excavator to balance budget and capability, benefiting from a machine that has proven reliability if properly maintained.

Mini excavators typically range from 1 to 6 tons in weight and come equipped with a variety of attachments, including buckets, augers, breakers, and grapples, enhancing their versatility. Their small footprint allows operation in restricted areas where larger equipment cannot fit, without compromising performance. Additionally, the diesel engines powering these machines deliver adequate power for common tasks while maintaining fuel efficiency.

Before operating any mini excavator, conducting a thorough pre-operation inspection is crucial. This ensures the machine's safety and optimal performance throughout the workday. The checklist includes:

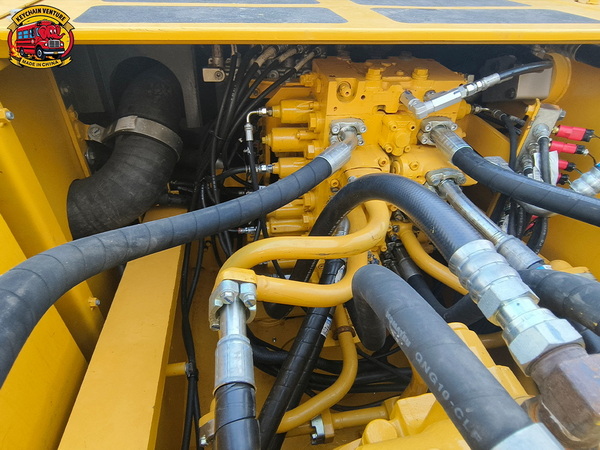

- Visual inspection: Check for any leaks, damages, or cracks in the boom, arm, hydraulic hoses, and bucket.

- Fluid levels: Verify engine oil, hydraulic fluid, coolant, and fuel levels.

- Track condition: Examine the rubber or steel tracks for wear and proper tension.

- Safety devices: Confirm that safety alarms, lights, and backup alarms are functioning.

- Controls and gauges: Test all control levers, pedals, and monitor display panel for normal operation.

This inspection should be done every day before starting work to prevent accidents and costly downtime. Look for loose or missing bolts and ensure the cab interior is clean, with unobstructed visibility. Checking the condition of attachments is also necessary, as worn buckets or hydraulic tools can affect operation quality.

The first step to using a mini excavator is starting it properly to avoid damage or unsafe conditions.

1. Enter the cab using designated handholds and steps to ensure safety.

2. Fasten the seatbelt; this is a mandatory safety step.

3. Insert the key and turn it to the "ON" position to power up controls and displays.

4. Monitor the startup sequence on the display panel; check for any system warnings or alerts.

5. Start the engine by turning the key fully and allow it to idle for a few minutes to reach optimal temperature.

Allowing the engine to idle helps lubricate vital components and ensures smoother operation once digging begins. Frequent stopping and starting without warming up can shorten engine lifespan and increase wear.

Understanding the controls is essential for safe and accurate mini excavator operation. Most models have dual joystick control systems complemented by foot pedals for tracking.

- Left joystick: Moves the boom up and down and swings the house left and right.

- Right joystick: Controls the arm's extension and retraction, as well as the bucket's curl and dump movements.

- Foot pedals: Propel the mini excavator forward and backward and assist in steering by varying track speed independently.

Understanding this layout is critical for learning more complex maneuvers such as pivot turns, grading, or fine digging.

Operators should practice these controls extensively in an open area before starting any excavation work.

Trenching is one of the primary tasks for mini excavators. To dig a trench:

1. Position the excavator close to the trench line but with enough space to swing the boom safely.

2. Extend the boom and arm forward with the bucket ready to scoop.

3. Pull the arm back while curling the bucket to scoop up soil.

4. Swing the house to the side and dump the soil in a designated spoil pile.

5. Lower the bucket and repeat, adjusting the depth as required for a uniform trench bottom.

Pay close attention to the machine's stability during trenching, especially on slopes or uneven ground.

Backfilling trenches and grading are secondary tasks that mini excavators can perform efficiently:

- Use the bucket edge to push soil into trenches or holes.

- Lower the boom and use the bucket to level the ground surface, smoothing out bumps.

- For finer grading, slightly tilt the bucket blade and move slowly to create an even finish.

These skills come in handy for landscaping projects or after utility installations.

Choosing a used excavator is a cost-effective way to acquire reliable equipment, especially for small businesses or startups. However, selecting and operating a used mini excavator requires careful consideration:

- Inspection for wear and tear: Look closely at the hydraulic seals, engine condition, track integrity, and frame for any structural damage.

- Maintenance history: Request detailed service records to determine how well the previous owner maintained the equipment.

- Test operation: Always conduct a walk-around test under various operational loads to identify hydraulic hesitations, engine performance, or control responsiveness issues.

- Warranty and support: Assess whether the seller offers any warranty or technical support after purchase.

Opting for a refurbished used excavator with certified refurbishing can provide peace of mind if budgets are limited.

Mini excavators can be equipped with various attachments that enhance their versatility, including:

- Augers: For drilling holes for fences or posts.

- Hydraulic breakers: To break concrete, asphalt, or rock.

- Thumbs or grapples: For picking up debris, logs, or demolition material.

- Rippers: For penetrating hard soil or frozen ground.

Each attachment requires specific handling techniques and safety protocols. Familiarize yourself with the attachment operation and maintenance before use.

Operating a mini excavator requires strict attention to safety guidelines to protect operators and bystanders:

- Always wear appropriate personal protective equipment (PPE), including hard hats, gloves, eye protection, high-visibility vests, and safety boots.

- Confirm the location of underground utilities by contacting local services before digging.

- Ensure the work zone is cordoned off to prevent unauthorized access.

- Avoid operating close to edges or slopes that could cause tipping.

- Communicate clearly with all crew members on site with hand signals or communication devices.

- Turn off the engine and secure the machine before leaving the operator's seat.

Incorporating these precautions reduces the risk of accidents and equipment damage.

Proper maintenance is key to ensuring your mini excavator remains reliable, especially when it is a used one. Daily and periodic tasks include:

- Lubricating all joints, pivot points, and links to reduce wear.

- Changing hydraulic and engine oil filters according to guidelines.

- Checking fluid levels and topping off as needed.

- Cleaning the radiator and cooling fans to prevent overheating.

- Inspecting track tension and adjusting to the manufacturer's specifications.

- Monitoring the electrical and control systems for fault codes or irregularities.

- Keeping the excavator clean from dirt, grease, and debris, especially in the cab and engine compartments.

A well-maintained machine delivers better performance and reduces costly repairs or downtime.

Using a mini excavator effectively involves mastering its controls, understanding common excavation tasks, and adhering to strict safety and maintenance protocols. For businesses or operators choosing a used excavator, it is critical to perform comprehensive inspections and verify maintenance history to ensure continued performance and safety. The integration of video tutorials throughout this guide can help operators quickly grasp operational techniques, making the transition from novice to skilled user smoother and more efficient. By combining knowledge, practice, and responsibility, operators can maximize the value and lifespan of their mini excavators.

Used excavators offer significant cost savings while still providing robust performance, especially when carefully inspected and maintained.

Routine checks should be daily, with comprehensive servicing every 250-500 hours of operation depending on manufacturer guidelines.

Basic training and familiarization with the controls are essential before operating for safety and efficiency.

Look for hydraulic leaks, worn track pads, slow or erratic movements, and unusual engine sounds.

Yes, videos provide step-by-step visual guidance, helping operators understand controls and techniques more quickly than text alone.