Content Menu

● Why Choose a Used Excavator?

● Key Components of a Used Excavator

>> Working Device: Boom, Arm, and Bucket

● Understanding Excavator Controls

>> Boom, Arm, and Bucket Motions

● Pre-Start Inspection of a Used Excavator

● Entering the Cab and Starting the Machine

>> Trenching with a Used Excavator

● Lifting and Material Handling

● Safety Best Practices for a Used Excavator

● Maintenance Strategy for a Used Excavator

● Technology and Productivity Features

● Buying Tips for a Used Excavator

● Frequently Asked Questions (FAQ)

>> 1. Is a Used Excavator reliable for daily construction work?

>> 2. How difficult is it to learn to operate a Used Excavator?

>> 3. What should be checked first when renting or buying a Used Excavator?

>> 4. Can a Used Excavator be equipped with modern attachments and technology?

>> 5. How can fuel consumption be reduced when operating a Used Excavator?

Operating an excavator is a foundational skill in construction, mining, landscaping, and infrastructure projects, and learning to operate a Used Excavator correctly can significantly reduce costs while maintaining high productivity. A well-chosen and well-maintained Used Excavator delivers the same core performance as many new machines when handled with proper technique, safety awareness, and disciplined maintenance. This article explains how to use a excavator from basic controls to advanced applications, with a strong focus on maximizing the value of a Used Excavator in real job-site conditions.[2][5][6][9]

An excavator is a hydraulic-powered machine designed to dig, lift, swing, and dump materials such as soil, rock, and demolition debris. It consists of an upper structure (house), an undercarriage, and a working device that includes boom, arm, and bucket, all connected through hydraulic cylinders and lines. Whether new or a Used Excavator, the basic operating principle is the same: an engine drives hydraulic pumps, which feed pressurized fluid to cylinders and motors to move each component precisely.[5]

Selecting a Used Excavator rather than a new machine can significantly lower capital expenditure, especially for small and medium-sized contractors. Because most heavy equipment loses a large share of its value in the early years, a Used Excavator tends to depreciate slower, offering a better long-term return on investment when properly inspected and maintained. When sourced from a professional supplier that tests and refurbishes machines, a Used Excavator can still deliver strong hydraulic performance, reliable engines, and modern safety features.[5]

The house holds the engine, hydraulic pumps, control valves, cab, and fuel and hydraulic tanks. This portion rotates 360 degrees on the slewing bearing and motor, allowing the Used Excavator to dig and dump without repositioning the tracks. The condition of the slewing ring, swing motor, and upper frame on a Used Excavator is vital, since wear in these areas can lead to play, noise, and reduced accuracy.[5]

The undercarriage consists of tracks or wheels, rollers, idlers, and final drives that transfer power to the ground. On a Used Excavator, track wear, roller play, and leaking final drives are common inspection points because they affect stability, travel speed, and operating safety. Proper track tension and periodic undercarriage cleaning extend the life of a Used Excavator and keep maneuvering smooth on soil, gravel, or rock.[6][5]

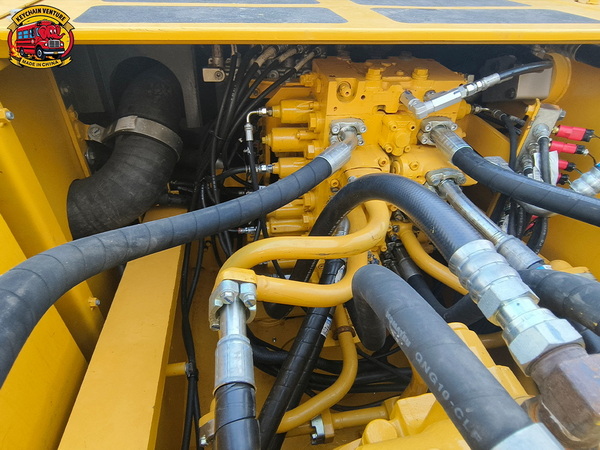

The boom provides vertical reach, the arm (or stick) controls horizontal distance, and the bucket handles cutting and carrying material. A Used Excavator may come with various attachments such as trenching buckets, rock buckets, hydraulic breakers, or compaction plates, and compatibility plus pin and bushing wear should be checked before purchase. The hydraulic cylinders that move boom, arm, and bucket must be inspected for leaks, rod scoring, and seal damage to ensure the Used Excavator maintains full digging power.[5]

Modern excavators typically use ISO or SAE joystick patterns, with ISO being the most common on many machines. In ISO mode, the left joystick usually controls swing and arm movement, while the right joystick manages boom and bucket functions, enabling smooth combined motions during digging. When using a Used Excavator, always confirm the current control pattern in the cab and test responses at low engine speed to avoid sudden or unexpected movements.[6][5]

Most tracked excavators use two travel levers or pedals: pushing both forward moves straight ahead, pulling both back reverses, and moving one more than the other turns the machine. Before traveling, ensure the boom is tucked in and close to the ground, keep the bucket low for stability, and avoid sharp turns on steep or soft ground, especially with a Used Excavator whose tracks may already be worn.[2][6]

Typical motions include lowering and raising the boom, extending and retracting the arm, and curling or dumping the bucket. Learning to feather joystick movements—making small, continuous inputs instead of abrupt pushes—gives the operator of a Used Excavator more precise control, reduces fuel consumption, and minimizes wear on hydraulic components.[8][6][5]

Routine pre-start inspections are even more critical on a Used Excavator than on a new unit. A structured walk-around helps detect leaks, structural fatigue, or mechanical problems before they become failures on the job site.[9][5]

Key inspection points include:

- Fluid levels: engine oil, hydraulic oil, coolant, and fuel, confirming there are no visible leaks around tanks and lines.[7][5]

- Hoses and fittings: look for cracks, wet spots, or rubbing that could cause sudden hydraulic loss while operating a Used Excavator.[5]

- Undercarriage: check track tension, sprockets, rollers, and idlers for excessive wear or missing bolts.[5]

- Attachments: inspect bucket teeth, cutting edges, pins, and bushings for damage or play.[5]

- Safety equipment: verify that mirrors, lights, horn, wipers, and seat belt operate correctly.[9]

When climbing into a Used Excavator, always use three points of contact and ensure the door is latched open or closed properly so wind cannot slam it. Once seated, fasten the seat belt, adjust the seat and armrests, and confirm that the safety lock lever is engaged before turning the key.[7][6]

After starting the engine, allow it to idle to warm up the hydraulic system and monitor the display for warning lights or fault codes. On a Used Excavator, warming the machine thoroughly helps protect older seals and reduces stress on pumps and valves when cold oil is thick.[6][9][5]

Place the excavator on firm, level ground whenever possible, aligning the tracks with the direction of digging so the house is centered over the undercarriage. Digging over the idlers is generally recommended to maintain stability and minimize stress on final drives, which is especially important for the lifespan of a Used Excavator.[9][6]

A basic dig cycle involves extending the arm, lowering the bucket, cutting into the soil, curling the bucket, lifting, swinging, and dumping. Beginners should practice slowly: extend the arm with the bucket teeth pointed down, lower into the soil, curl the bucket to fill, raise the boom to clear obstacles, swing toward the dump area, and then uncurl to release material. Repeating this cycle smoothly helps operators get familiar with the timing and hydraulic response of a Used Excavator while keeping the machine stable and fuel use efficient.[6][5]

For trenching, align the tracks parallel to the trench path and start from the farthest point from the machine, working back toward the excavator. Maintain a consistent trench width and depth by controlling the arm angle and bucket curl, and avoid over-digging, which requires extra backfilling and stresses the Used Excavator unnecessarily.[2][6][5]

Backfilling can be performed by reversing the digging process—pushing soil back into the trench with controlled bucket sweeps. Operators of a Used Excavator should avoid scooping aggressively during backfilling; instead, use the bucket's back or side to spread material evenly and finish with light passes for grading.[2][6][5]

Grading demands feather-light joystick inputs and careful boom and arm coordination to shave thin layers of soil. A Used Excavator can perform fine grading by keeping the bucket flat and dragging or pushing small amounts of soil, but sudden changes in depth or aggressive movements can create uneven surfaces and strain hydraulic components. When working on slopes, always keep the heavy end of the machine (usually the boom and upper structure) uphill, travel slowly, and avoid side-hill operations with a raised load.[8][9][6][5]

Many contractors use a Used Excavator as a lifting machine for pipes, precast elements, or beams. Before lifting, consult the load chart, use appropriate lifting points or hooks, and ensure the machine is on stable, level ground with the blade or tracks positioned for maximum stability. Loads should stay close to the ground, and swinging quickly with a suspended load must be avoided to prevent tipping and structural stress, especially on older machines.[9]

Safety is central to operating any excavator, and age or previous usage history of a Used Excavator makes consistent safety habits even more important.[9][5]

Key practices include:

- Wearing PPE such as hard hats, safety boots, high-visibility clothing, gloves, and eye protection.[9]

- Establishing exclusion zones so no one walks under the boom or works inside the swing radius of the Used Excavator.[9]

- Maintaining clear communication using radios or agreed hand signals between the operator and ground crew.[9]

- Locating underground utilities before digging, using maps, markings, and, when required, professional detection services.[9]

- Never using the bucket or attachment to carry passengers or lift people.[9]

Daily tasks for a Used Excavator include checking fluid levels, inspecting hoses and cylinders, looking for fresh leaks, cleaning the undercarriage, and greasing all pivot points. Weekly routines should verify track tension, bucket pin wear, air filter condition, and battery terminals, noting any abnormal noises or vibration during operation.[7][5]

Manufacturers often recommend periodic replacement of engine oil, hydraulic oil, fuel filters, and coolant based on operating hours. On a Used Excavator, respecting or even slightly shortening these intervals helps offset the natural wear of older components and reduces the chance of unplanned downtime in demanding environments. Keeping detailed maintenance records not only extends machine life but also supports higher resale value when the equipment is upgraded later.[5][9]

Many modern machines—and some upgraded Used Excavator models—include GPS guidance, semi-automatic grade control, and telematics systems. These technologies help operators maintain target depths, monitor fuel use, track idle time, and schedule maintenance more accurately, improving total cost of ownership. Even without advanced electronics, simple habits such as planning the work sequence, minimizing unnecessary travel, and practicing smooth control greatly enhance productivity with a Used Excavator.[8][5]

New operators of a Used Excavator often make predictable errors that can lead to repairs or safety incidents. Common mistakes include digging or traveling at maximum throttle all the time, ignoring early signs of leaks, lifting loads beyond the rated capacity, and driving with the boom high rather than close to the ground. Avoiding these habits protects both the machine and the crew, and it is especially important with a Used Excavator that may already have some wear in the structure and hydraulics.[2][6][5][9]

Professional training programs teach operators not only which levers to move but also how to read soil conditions, control swing momentum, and manage blind spots. Even if a Used Excavator is operated in private or remote projects, having trained personnel reduces repair costs, fuel consumption, and accident risk, and helps ensure compliance with local safety regulations.[4][9]

Before committing to a Used Excavator, a structured evaluation helps distinguish a good machine from an expensive problem. Prospective buyers should:[5]

- Inspect the engine for excessive smoke, unusual noise, or low power during test operation.[5]

- Check hydraulic performance by performing dig, swing, and travel functions at working temperature to detect slow response or cavitation.[5]

- Examine the boom, arm, and frame for weld repairs, cracks, or bent sections.[5]

- Confirm operating hours and cross-check them with visible wear on pedals, controls, and pins.[5]

Working with a reputable dealer that provides inspection reports, service history, and possibly a limited warranty greatly reduces risks when purchasing a Used Excavator.[5]

Using an excavator efficiently is a combination of technical knowledge, practical experience, and strict adherence to safety and maintenance standards. A well-selected and well-maintained Used Excavator can deliver excellent performance in digging, trenching, grading, lifting, and backfilling while requiring far less investment than a brand-new machine. By mastering the controls, performing thorough pre-start inspections, applying best-practice digging and backfilling techniques, and following a disciplined service schedule, operators and owners can unlock the full value of a Used Excavator on every project.[6][9][5]

Yes, a Used Excavator can be reliable for daily use if it has been properly maintained, inspected for structural and hydraulic issues, and serviced according to manufacturer guidelines. Choosing a unit with documented service records and having a mechanic evaluate critical components such as the engine, pumps, and undercarriage greatly improves reliability.[5]

Most beginners can learn basic excavator movements within a few days of supervised practice, especially on machines with modern, intuitive joystick controls. However, achieving professional-level productivity and precision with a Used Excavator typically requires additional training and many hours of experience in real job-site conditions.[4][7][2][6]

The first checks should include engine condition, hydraulic performance, undercarriage wear, and any visible structural damage such as cracks or poor weld repairs. You should also review maintenance records, confirm operating hours, and test all functions at working temperature to ensure the Used Excavator performs smoothly without abnormal noise or hesitation.[5]

Many Used Excavator models are compatible with current hydraulic attachments such as breakers, thumbs, augers, and tilt rotators, as long as flow and pressure requirements match the base machine. In addition, some units can be upgraded with aftermarket telematics, grade control systems, and safety cameras, bringing older machines closer to modern performance and monitoring standards.[5]

Fuel use can be lowered by operating at appropriate engine speeds, planning efficient work cycles, reducing unnecessary idling, and avoiding abrupt, full-stroke control inputs. Regular maintenance—such as cleaning air filters, maintaining correct hydraulic oil levels, and ensuring track tension is set correctly—also helps a Used Excavator run more efficiently and consume less fuel per cubic meter of material moved.[8][5]

[1](https://www.youtube.com/watch?v=QWvKa1Bkak8)

[2](https://www.heavymetallearning.com/blog/how-to-operate-an-excavator)

[3](https://www.youtube.com/watch?v=uutTJgY7Br0)

[4](https://heavyequipmentcollege.edu/how-to-operate-an-excavator/)

[5](https://www.sanyglobal.com/blog/how-to-operate-excavator/)

[6](https://www.bigrentz.com/blog/excavator-controls)

[7](https://equipmentsource.net/how-to-operate-a-mini-excavator/)

[8](https://www.fjdynamics.com/fr/blog/industry-insights-65/excavator-controls-521)

[9](https://www.hopenn.com/blog/how-to-operate-a-cat-excavator/)

[10](https://www.ltmgloader.com/step-by-step-excavator-operation-guide-for-beginners)

Field Visit To DR Congo – Products in Action, Friendships in Progress

Treat Your Team to the Perfect Ending: A Cultural Day & Rejuvenating Massage

Just received this absolutely gorgeous bouquet specially ordered by our lovely customer!

Truly inspiring conversations today with our highly insightful client!

Today, we visited the bus company together with our client. It was really wonderful!

A Milestone Moment: Custom Buses Successfully Shipped, Setting Course for New Horizons

Forging Stronger Ties: Welcoming Key African Partners to Chongqing for Transport Collaboration