Views: 222 Author: Amanda Publish Time: 2025-08-21 Origin: Site

Content Menu

● How Rain Affects Excavator Operation

>> 2. Slippery Ground Conditions

>> 3. Electrical and Hydraulic System Vulnerability

>> 4. Reduced Traction and Stability

>> 5. Soil Compaction and Damage

● Safety Precautions When Using Excavators in Rain

>> 1. Perform Pre-Operation Inspections

>> 2. Use Slow and Careful Maneuvering

>> 4. Maintain Clear Communication

>> 5. Utilize Lighting Systems

● Maintenance Tips for Used Excavators in Wet Conditions

>> 1. Check and Replace Seals and Gaskets

>> 2. Clean the Undercarriage Regularly

>> 3. Inspect and Maintain Electrical Components

>> 4. Monitor Hydraulic Fluid Levels and Quality

>> 5. Lubricate Moving Parts Frequently

>> 6. Inspect Air Filters and Engine Compartments

● Optimizing Excavator Performance in Rain

>> 1. Choose the Right Tracks or Tires

>> 2. Keep Equipment Covered During Breaks

>> 3. Use Attachments Suitable for Wet Conditions

>> 4. Monitor Soil Conditions Continuously

>> 5. Train Operators on Rain-Specific Techniques

>> 6. Implement Site Drainage Solutions

● FAQ

>> 1. Can rain damage a used excavator?

>> 2. How should I clean my used excavator after working in the rain?

>> 3. Is it safe to operate a used excavator on muddy terrain?

>> 4. What maintenance is most important after using an excavator in the rain?

>> 5. Should I delay excavation work when heavy rain is expected?

Operating heavy machinery like excavators requires not only skill but also a clear understanding of environmental constraints. One common question, especially for those who purchase or rent used excavators for construction, landscaping, or commercial projects, is: Can you use an excavator in the rain? This article explores this question in depth, providing practical advice and safety guidelines to help you make informed decisions when working with excavators in wet weather conditions.

Excavators are essential machines that perform a variety of tasks on construction and excavation sites. Used excavators are especially popular due to their affordability and availability. Yet, the question about using these machines during rainy conditions is critical for both safety and machine longevity.

Rain causes surface water, mud, and slippery conditions which can challenge the stability and efficiency of excavators. However, with the right knowledge and precautions, it is possible to operate used excavators safely in the rain. Below, we will discuss the effects of rain on excavators, the necessary safety precautions, maintenance to prevent damage, and best practices for use.

Rain can significantly impact the operation of excavators in several ways:

Rain can severely reduce visibility, making it difficult for operators to see clearly and judge distances accurately. Water droplets can obscure the operator's line of sight, especially through glass panels or cameras, which increases the risk of accidents. Operators may struggle to spot hazards, moving worksites equipment, or changes in terrain that could affect machine stability.

Rain saturates the ground, creating mud and reducing traction. Wet clay or loam soils become especially challenging, turning into slick surfaces that make maneuvering the excavator difficult. This may cause the excavator to slip or get stuck, especially on slopes or uneven terrain. Sites near water bodies or low-lying areas often experience waterlogging, further complicating operations.

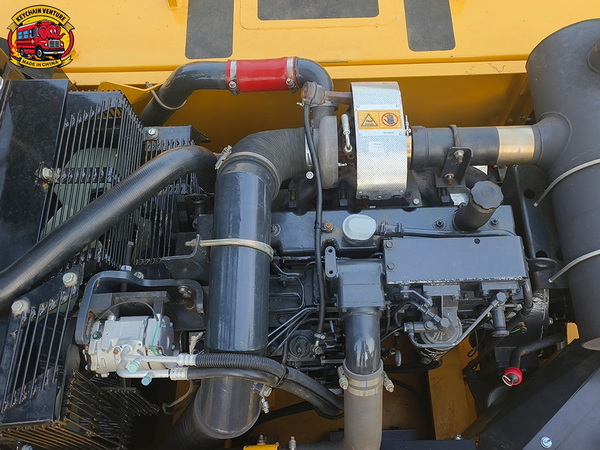

Although excavators are designed to withstand various weather conditions, prolonged exposure to rain can lead to moisture infiltration affecting the electrical system or hydraulic components. This is especially critical for older or used excavators that might have worn seals, aging insulation, or previous undocumented damage, increasing the risk of short circuits, corrosion, or hydraulic leaks.

Wet surfaces reduce the grip of the tracks or tires, lowering the machine's stability. This increases the risk of tipping hazards during excavation or lifting operations, especially when working on uneven terrain or lifting heavy loads. The ramp-up and braking distances also increase, requiring more controlled operation.

Excavators exert high ground pressure, and operating on wet soil can lead to excessive soil compaction—damaging the site and creating uneven ground that becomes difficult to work on later. This is problematic in landscaping or agricultural applications where soil structure integrity is essential.

To safely operate used excavators in rain, follow these precautionary measures:

Daily inspections are essential before starting work in rainy conditions. Check the condition of hydraulic hoses for cracks or leaks caused by repeated moisture exposure. Inspect all electrical wiring, connectors, and switches for loose connections or corrosion. Ensure that all lights, including headlamps and rear lights, are operational for enhanced visibility.

Operators should reduce speed, especially on slopes or muddy surfaces. Avoid sudden starts, sharp turns, or abrupt stops, as these actions can trigger slipping or loss of control. Maintaining consistent and smooth operation reduces stress on drive components and improves stability.

Operators must wear waterproof gear, including gloves and boots with excellent traction, to maintain safety inside and outside the cabin. High-visibility waterproof clothing improves safety by making the operator more noticeable to other workers on site.

Rain can hinder verbal communication due to ambient noise. Use radios with noise-cancelling features or agreed-upon hand signals to communicate effectively with ground crews. Keeping clear communication helps avoid accidents and coordinate efforts safely.

Always use your excavator's lighting system during poor visibility conditions caused by rain or overcast skies. Consider adding auxiliary lights if the worksite is particularly dim or during early morning or late evening operations.

Avoid working in areas prone to flooding, deep mud, or unstable slopes during rainy weather. Evaluating the site ahead of time helps in identifying potential hazards and scheduling work in the safest and most efficient manner.

Proper maintenance can extend the life and performance of a used excavator operating in rainy conditions:

Rainwater can infiltrate through worn seals and gaskets causing electrical and mechanical damage. Regularly inspect these wear-points and replace any worn or damaged seals to prevent moisture ingress, especially in hydraulic cylinders and engine compartments.

Mud and debris can accumulate in the undercarriage after working in wet, muddy conditions. This increases wear on tracks, rollers, sprockets, and idlers. Use appropriate flushing methods to clean out the debris regularly to prevent premature failure.

Electrical circuits, battery terminals, and fuse boxes in used excavators should be kept dry and free of corrosion. Apply dielectric grease to connectors and seal vulnerable areas with waterproof covers or sealants. This prevents malfunctioning and costly repairs.

Water contamination in hydraulic fluid is a common issue when working in wet environments. It can reduce lubrication effectiveness and cause internal corrosion. Regularly check the fluid for signs of contamination and replace filters and fluids on schedule.

Rain and mud accelerate rust and erosion on pins, bushings, and joints. Carry out frequent greasing of all moving parts, including boom, arm, bucket joints, and slew rings to maintain smooth operation and protect against corrosion.

Operating in the rain can cause moisture to enter air filters or engine compartments. Check and replace air filters more often to maintain engine performance and reduce the risk of internal damage.

Here are practical strategies to maximize efficiency when using used excavators during rainy days:

Rubber tracks offer better traction and surface protection on wet and slippery terrain compared to steel tracks. Assess your site conditions and choose tracks or tires best suitable to balance traction and ground disturbance.

When not in use for extended periods during rainy spells, park the excavator under shelter or use covers to protect sensitive components from continuous exposure. This practice reduces corrosion and electrical issues.

Buckets with teeth designed for digging in soft, water-saturated soils improve efficiency. Specialized attachments like rock rippers or mud buckets can be considered to increase productivity in adverse conditions.

Wet soil strength varies throughout the rain event. Operators should be trained to adjust excavation depth, force, and speed according to soil consistency to avoid overloading and getting stuck.

Operators skilled in wet weather operation tend to minimize risks by understanding excavation nuances such as sloping, load distribution, and machine balancing on slippery surfaces.

For extended projects in rainy climates, improving site drainage or temporary hardening (such as gravel mats) prevents water accumulation and stabilizes ground for safer excavation.

When operating excavators in the rain, avoid these common mistakes:

- Ignoring Weather Forecasts: Failing to check upcoming rain can lead to unplanned hazardous work conditions.

- Skipping Safety Checks: Overlooking inspection steps increases mechanical failure risks and operator hazards.

- Overloading the Excavator: Wet soil adds extra suction and weight, making it easier to overload and strain the machine.

- Poor Ground Assessment: Misjudging soil softness or slope can cause tipping or sinking accidents.

- Delayed Maintenance: Neglecting cleaning and lubrication after rainy shifts accelerates wear, rust, and system failures.

- Using Improper Attachments: Using attachments not suited for wet soils reduces operational efficiency and increases wear.

Using a used excavator in the rain is entirely feasible with the right preparation, precautions, and maintenance. Rainy conditions inherently create challenges such as reduced traction, visibility issues, and increased maintenance needs. However, detailed safety checks, appropriate operational techniques, and ongoing maintenance can ensure excavators perform safely and effectively in wet weather.

Not only do these practices protect operators, but they also prolong the machine's longevity, allowing your investment in used excavators to deliver reliable performance regardless of weather challenges. By choosing the right equipment, adapting to site conditions, and keeping safety top of mind, rain doesn't need to halt your excavation projects.

Rain itself is unlikely to cause immediate damage because excavators are designed for outdoor use. However, prolonged exposure, especially in older used excavators, can lead to water entering electrical systems or cause rust if maintenance is neglected.

After rainy operations, thoroughly rinse the undercarriage to remove mud and debris. Inspect hydraulic and electrical components for moisture, drying or lubricating them as needed to prevent corrosion and malfunction.

Operating on muddy terrain increases slipping and sticking risks. Slow, cautious maneuvers, along with the right track types and attachments, improve safety and reduce hazards.

Focus on inspecting hydraulic seals, electrical insulation, undercarriage cleanliness, and lubrication of critical moving joints. Regular fluid checks prevent contamination problems.

Delayed work during heavy rain is advisable to ensure safety and protect equipment. Planning around weather forecasts minimizes accidents and wear from adverse site conditions.