Views: 222 Author: Amanda Publish Time: 2025-11-13 Origin: Site

Content Menu

● What Makes Mini Excavators Intuitive?

>> Key Features that Aid Usability

● Step-by-Step: Operating a Mini Excavator

>> 1. Pre-Operation Safety Checks

>> 2. Starting and Getting Ready

>> 3. Movement and Maneuvering

● Advanced Techniques: Maximizing Productivity with a Used Excavator

● The Proven Value of Used Excavators

>> Advantages of Used Excavators

>> What to Check When Buying Used

● Mini Excavator Attachment Options

● Common Mini Excavator Projects

● Tips for First-Time Operators

● Used Excavator: The Ultimate Solution for Small Contractors

● FAQ

>> 1. How long does it take to learn to operate a mini excavator?

>> 2. What checks are essential before running a used excavator?

>> 3. Can attachments be used on all mini excavators, including used models?

>> 4. Is maintenance for a used excavator more complicated than a new one?

>> 5. What tasks are mini excavators best suited for?

Mini excavators, especially those purchased as a Used Excavator, are now essential tools on construction sites, landscaping projects, utilities installations, and demolition jobs worldwide. Their compact size and powerful capabilities make them ideal for professionals and DIY users alike, enabling precise earthmoving in restricted areas. This guide provides a detailed, practical explainer about the usability, operation, and best practices for using mini excavators—covering both new and used models while highlighting essential safety procedures, maintenance, and purchasing advice.[7][11][12]

Mini excavators are designed with user-friendly controls, ergonomic cabins, and straightforward maintenance requirements, contributing to their accessibility for both novice and experienced operators. Used excavators, when properly maintained, retain these benefits and offer added economic advantages.[3][12][7]

- Simple control layout: Mini excavators use two main joysticks (ISO/SAE patterns) that replicate the operation of larger machines, allowing easy learning transfer.[1][6][7]

- Compact size: Designed to fit into residential backyards, urban construction sites, and tight job zones.

- Transportable: Many models, including used excavators, can be hauled with pickup trucks or on small trailers.

- Versatility: Accept a wide range of attachments, from buckets to hydraulic thumbs.[13]

- Visibility: Modern mini excavators prioritize a clear view from the cab to enhance safety and ease of operation.[11][12][3]

Always inspect the excavator before use, especially if operating a used excavator. This ensures maximum safety and minimizes unexpected breakdowns.[5][14][7]

- Check fluid levels: engine oil, hydraulic fluid, coolant.

- Examine the undercarriage for worn tracks or visible damage.[3]

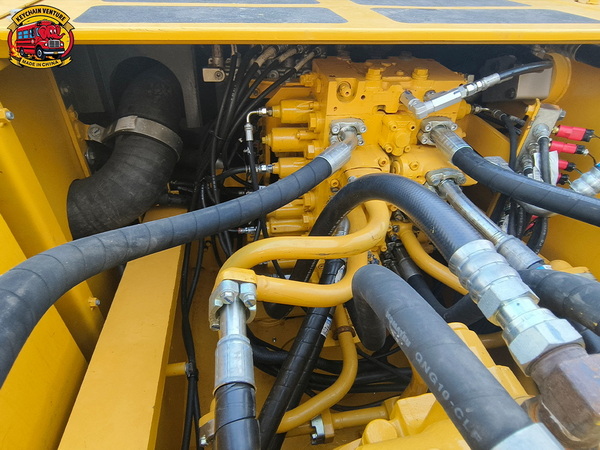

- Inspect hydraulic lines and connections for leaks.

- Confirm functionality of controls and attachment locks.

- Maintain three points of contact when entering the cab.

- Adjust the seat, fasten the seatbelt, and familiarize yourself with control layouts.[8][7]

- Close the cab door for operator safety and dust reduction.[8]

- Lower the safety lock lever to activate controls.

Mini excavators feature pedals or drive levers to allow forward and reverse movement. Use the following steps for basic driving and maneuvering:[6][5]

- Turn the ignition to start the engine; allow a brief idle for hydraulic warmup.

- Raise the stabilizer blade for transit.

- Use the drive levers to move tracks: push both forward to advance, pull back to reverse.

- To turn, push one lever forward while pulling the other back.

Digging with a mini excavator is manageable even for first-timers. Used excavators often retain strong digging power and precision.[4][10][7]

- Lower the dozer blade to stabilize.

- Extend the stick out by moving the left joystick forward.

- Lower the boom with the right joystick until the bucket teeth touch the ground.

- Curl the bucket using the right joystick to scoop; simultaneously retract the stick for efficient earthmoving.

- Practice coordinating joystick movements for smooth digging and efficient loading.

- Raise the boom and swing the cab using the left joystick to position over the spoil pile.

- Dump the load by curling the bucket out.

- Bring the bucket and arm back down to the ground.

- Turn off the ignition and secure the cab.

Operating a used excavator provides economic value and job-site efficiency when advanced techniques are employed.[15][16][17]

- Practice gentle transitions between digging and swinging for smoother operation.

- Use auxiliary hydraulics for specialized attachments.

- Adjust throttle for tougher jobs—start with half power while in training.[4][3]

- Deploy the rabbit button for quick, straight-line repositioning between tasks.

Opting for a used excavator can be a game-changer for small businesses and cost-conscious contractors. Used equipment often provides immediate availability, reliable performance, and proven designs that withstand demanding work cycles.[16][17][18][15]

- Lower purchase price.

- Immediate project deployment.

- Reduced depreciation risk.

- Often lower insurance rates.

- Strong resale value for reputable brands.

- Wide selection across models and attachments.

- Confirm maintenance history and operational hours.[14][19]

- Inspect for cracks, leaks, or undercarriage wear.

- Test all controls and safety features.

- Compare different models for best fit and reliability.[17][15]

Both new and used excavators accept a multitude of attachments, broadening their utility on job sites.[13][16]

- Hydraulic thumbs for grappling.

- Augers for drilling holes.

- Grapples for handling debris.

- Trenching buckets for pipe laying.

Mini excavators—particularly used models—excel in a variety of roles:[20][21][13]

- Trenching for pipe and cable installation.

- Landscaping work, such as tree removal and grading.

- Small structure demolition.

- Site cleanup and material handling.

- Pool and pond digging.

Proper maintenance is essential for the longevity and reliability of a used excavator.[19][7][14]

- Perform daily fluid checks.

- Grease all pivot points regularly.

- Inspect tracks and undercarriage after each job.

- Clean the cab and controls after use.

- Schedule periodic professional inspections.

Safety is paramount, especially when operating any used excavator, where unexpected quirks may exist due to wear or unique modifications.[22][23][14][19]

- Always wear PPE: including hard hats, gloves, steel-toed boots, and eye protection.[23][22]

- Mark jobsite boundaries, highlighting any buried utilities or hazards.

- Never exceed rated lift capacities or dig outside recommended angles.

- Practice egress from cab using three points of contact.

- Shut down and secure equipment after each use.

Beginner users will find mini excavators—used or new—intuitive, reliable, and efficient when following these guidelines:[6][3][4]

- Read the instruction manual thoroughly.

- Watch operation video tutorials for hands-on reference.[24][25][20]

- Start practicing on level ground.

- Use half throttle for initial learning.

- Get comfortable with the cab layout and joystick controls before attempting complex tasks.

Mini excavators purchased as used machines can deliver the performance of new units at a much lower cost. They are perfect for small contractors, utility companies, municipal jobs, and homeowners tackling extensive landscaping projects. Their lower operating and acquisition costs provide better budget control.[15][16][17]

Mini excavators are remarkably easy to use, thanks to ergonomic design, simple controls, and intuitive operation. Whether purchasing new or investing in a used excavator, operators benefit from versatility, safety, and efficiency for all manner of digging, landscaping, and material handling tasks. Used excavators provide substantial value by combining reliability, immediate availability, and cost savings while retaining compatibility with a vast array of attachments. With routine inspection, safe operating procedures, and a methodical approach to maintenance, mini excavators will remain a centerpiece of modern job sites for years to come.

Most beginners are comfortable using a mini excavator within one to two hours of guided practice, especially with hands-on tutorials and straightforward controls. Used excavators may require familiarization with specific model quirks, but basic operations remain easy to learn.[10][7][4]

Always inspect fluid levels, hydraulic lines, tracks, and electrical systems. Reviewing maintenance history and operational hours is critical to ensure safe and reliable usage.[5][14][19]

Most mini excavators, new or used, support a variety of attachments. Confirm that the attachment matches the excavator's hydraulic and mounting specifications for optimal performance.[16][13]

Maintenance is similar, but used excavators should be monitored more closely for wear, leaks, and irregular noises. Regular lubrication, fluid checks, and periodic professional inspections help maximize machine life.[7][14][19]

Mini excavators excel at trenching, grading, landscaping, demolition of small structures, and material handling in confined spaces. Used excavator models are especially useful for municipal, residential, and utility jobs where both precision and compact maneuverability are required.[11][20][13]

[1](https://www.youtube.com/watch?v=dLoIwRKaj80)

[2](https://www.youtube.com/watch?v=zb9D-TVtyT8)

[3](https://www.quinncompany.com/mini-excavator-operating-tips-how-to-use-a-mini-excavator/)

[4](https://diggermate.com/mini-excavator-controls/)

[5](https://www.fjdynamics.com/es/blog/industry-insights-65/construction-how-to-operate-mini-excavator-684)

[6](https://www.bigrentz.com/blog/how-to-operate-mini-excavator)

[7](https://dozr.com/blog/how-to-operate-a-mini-excavator)

[8](https://www.unitedrentals.com/project-uptime/equipment/how-operate-excavator-or-mini-excavator)

[9](https://www.youtube.com/watch?v=oyyJGuBqVtM)

[10](https://www.wikihow.com/Operate-a-Mini-Excavator)

[11](https://www.bobcat.com/na/en/buying-resources/excavators/compact-excavator-buyers-guide/what-is-compact-mini-excavators)

[12](https://www.kmcequipment.com/blog/benefits-of-the-mini-excavator--66683)

[13](https://typhonmachinery.com/10-awesome-ways-to-use-mini-excavators/)

[14](https://www.eaglepowerandequipment.com/blog/2018/12/tips-for-buying-a-used-excavator/)

[15](https://deepkron.com/blog/new-vs-used-mini-excavator-for-sale-pros-cons-guide/)

[16](https://www.arizonatractorsales.com/blog/the-advantages-of-choosing-a-used-excavator--84139)

[17](https://ahmcorp.com/blogs/news/new-vs-used-mini-excavator)

[18](https://www.mechandlink.com/en/news-article/The-Allure-of-Used-Excavators-A-Comprehensive-Guide)

[19](https://www.rdoequipment.com/resources/blogs/the-used-excavator-trend-and-tips-to-a-successful-buy)

[20](https://diggermate.com/5-tips-in-operating-a-mini-excavator/)

[21](https://sniperrentals.com/blogs/news/pros-and-cons-of-mini-excavators-in-2024)

[22](https://www.clevelandbrothers.com/blog/top-safety-tips-for-mini-excavators)

[23](https://nmccat.com/blog/equipment-and-solutions/mini-excavator-safety-tips/)

[24](https://www.youtube.com/playlist?list=PLgtjFAc5rG7uavAub_p42wmwFnn4PiCVO)

[25](https://www.tiktok.com/@nuoman_excavator/video/7511976404729236743)