Views: 222 Author: Amanda Publish Time: 2025-08-21 Origin: Site

Content Menu

>> 6. Forestry

● Extended Uses of Excavators in Specialized Applications

● Benefits of Using a Used Excavator

● Industries Relying on Excavators

● Key Features and Attachments of Excavators

● Maintenance Tips for a Used Excavator

● FAQs

>> 1. What factors should I consider when buying a used excavator?

>> 2. How long does a used excavator typically last?

>> 3. Can attachments from new excavators be used on used ones?

>> 4. What are the main advantages of using a crawler excavator over a wheeled one?

>> 5. How can maintenance reduce operational costs of a used excavator?

Excavators are one of the most essential and versatile pieces of equipment in the construction, mining, and industrial sectors. Whether you are working on heavy highway construction, residential building projects, or large-scale mining operations, the used excavator remains a critical asset that boosts productivity and efficiency. In this article, we will explore the various applications of excavators, focusing particularly on the value and utility of a used excavator for commercial vehicle suppliers, construction firms, and contractors worldwide.

An excavator is a heavy-duty machine commonly used for digging, lifting, and moving large objects. It typically consists of three main components: a cab on a rotating platform, an articulated arm with a bucket or attachment at the end, and the undercarriage with either tracks or wheels. Originally designed for digging trenches, the technology has evolved, and these machines can now perform a wide variety of tasks.

For companies like KeyChain Venture Co., Ltd., a leading supplier of commercial vehicles including heavy trucks and passenger buses, understanding the multiple uses and the strategic advantage of a used excavator means offering customers equipment that maximizes operational efficiency at competitive costs.

Excavators come in several types, each designed for specific applications. Choosing the right kind depends on the nature of the work, terrain, and project requirements.

- Crawler Excavators: These have tracks instead of wheels, providing better stability on rough or muddy terrains, ideal for construction sites.

- Wheeled Excavators: More mobile than crawler types, suitable for urban construction where fast movement between locations is needed.

- Mini Excavators: Compact and highly maneuverable, these are perfect for tight spaces such as residential renovations.

- Long Reach Excavators: Designed for dredging or deep digging over a distance.

- Dragline Excavators: Used mainly in mining and large-scale civil engineering projects for deep digging operations.

A used excavator can be found across all these categories, available with different specifications and attachments to fit a wide range of needs.

Excavators are primarily used for digging trenches, foundations, and holes. This is perhaps their most iconic function where the bucket attachment scoops and moves earth rapidly. Excavation is the backbone of construction and infrastructure work, making excavators indispensable on virtually every site. A properly selected used excavator can handle everything from small-scale digs to major infrastructure projects, providing flexibility and power.

With appropriate attachments such as hydraulic breakers or shears, excavators can efficiently demolish buildings and concrete structures. Their strength and reach enable safe dismantling with precision, reducing the risk to workers and speeding up project timelines. Demolition work with a used excavator also includes sorting and loading debris for removal or recycling, enhancing the workflow continuity on demolition sites.

Excavators are frequently used to load materials such as soil, rocks, and debris into trucks or stockpile them for later use. This form of heavy material handling reduces manual labor and increases the speed and efficiency of transporting materials on-site. The use of grapples or clamshell buckets on a used excavator can further enhance handling capabilities for different materials.

In mining operations, excavators strip the ground and extract minerals or ores. Their power and reach make them suitable for large-scale extraction work where continuous digging and loading dominate. The availability of durable used excavators equipped with reinforced attachments allows mining companies to benefit from high machine uptime at reduced investment costs.

Mini excavators help with landscaping tasks including tree planting, stump removal, and shaping terrains for gardens and parks. These smaller machines provide sufficient power with minimal disturbance to surrounding areas, which is essential in horticultural and landscaping projects. A used excavator with compact design suits contractors specializing in urban and residential landscaping.

Specialized excavator attachments enable tasks such as log handling, tree harvesting, and land clearance in forested areas. Forestry companies often rely on excavators fitted with grapples and mulchers to expedite land preparation for planting or to assist in timber extraction. Purchasing a used excavator with appropriate forestry attachments can reduce capital expenditure while expanding operational capability.

Excavators play a critical role in road construction projects by digging roadbeds, removing old pavement, assisting in grading, and site preparation. The machines also help install utilities such as drainage pipes and cables by digging trenches with precision. Renting or buying a used excavator specifically suited for roadwork offers contractors economical access to powerful earthmoving equipment.

Beyond the common construction, mining, and agriculture uses, excavators serve in more specialized roles:

- Pipeline Installation: Excavators dig trenches for large-scale pipeline projects transporting water, oil, and gas. Their ability to work in various soil conditions and depths is crucial for efficient pipeline laying.

- Disaster Response and Cleanup: In aftermath situations such as floods or earthquakes, excavators clear debris, stabilize structures, and assist in rescue operations.

- Environmental Remediation: Excavators equipped with special buckets help remove contaminated soil or dredge silt from water bodies as part of cleanup efforts.

- Port and Marine Construction: Long reach excavators manage dredging and construction of ports, docks, and seawalls, reaching underwater sediments effectively.

These applications highlight the flexibility of excavators, confirming why a used excavator represents a wise investment across diverse industrial sectors.

Purchasing a used excavator offers several advantages to businesses looking to expand their fleet affordably without compromising performance:

- Cost Efficiency: Significant savings compared to buying new equipment without sacrificing functionality.

- Depreciation: Used machines have already undergone major depreciation, retaining more value over time.

- Immediate Availability: No long lead times for manufacturing; this is particularly beneficial for urgent project deadlines.

- Proven Reliability: Many used models have demonstrated dependable performance on job sites, especially those maintained under strict service schedules.

- Wide Variety: Access to different brands, sizes, and configurations within budget allows buyers to match machines with precise operational needs.

- Environmental Advantages: Extending the lifecycle of machinery indirectly supports sustainability goals by reducing waste and resource consumption.

Companies like KeyChain Venture Co., Ltd. can help clients maximize return on investment by offering a diverse portfolio of quality used excavators, which form a cornerstone of many construction and industrial fleets.

Excavators are widely used across various industries, including:

- Construction: Residential, commercial, and infrastructure projects.

- Mining: Surface and strip mining require robust excavation equipment.

- Agriculture: Land clearing, terracing, irrigation, and drainage tasks.

- Forestry: Timber harvesting and land management activities.

- Utilities: Trenching for pipelines, cables, and other underground utilities.

- Waste Management: Handling and moving waste materials at landfill and recycling sites.

- Manufacturing: Site preparation and material handling in heavy industrial complexes.

- Transportation Infrastructure: Railroads, airports, and ports use excavators for both construction and maintenance.

Their unmatched versatility makes excavators a backbone of heavy equipment fleets worldwide.

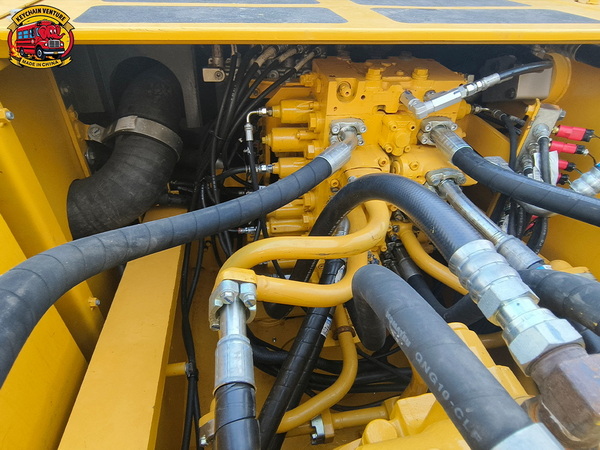

- Hydraulic System: Powers the arm and attachments, allowing precise control of digging and lifting with smooth operation.

- Rotating Cab: Provides 360-degree movement to access different work zones without repositioning the entire machine.

- Tracks or Wheels: Determines mobility and site suitability; crawler tracks excel on uneven terrain, whereas wheels allow faster travel on paved surfaces.

- Engine Power: Affects digging capacity and operational efficiency; larger engines deliver more force and longer operation times.

- Operator Comfort: Modern excavators feature climate-controlled cabs, ergonomic controls, and advanced monitoring systems to improve operator productivity.

Modern excavators can be equipped with various attachments, significantly increasing their multi-functionality:

- Standard and Specialty Buckets: Digging, cleaning, trenching, or rock handling buckets designed for specific materials and jobs.

- Hydraulic Breakers: Effective for breaking concrete, rocks, and old pavements in demolition and quarrying.

- Grapples: For sorting and handling debris or logs, ideal in forestry and recycling.

- Augers: Used for drilling deep holes in soil for planting or installing poles and foundations.

- Thumb Attachments: These improve grip to securely handle irregular objects or large debris.

The availability of these attachments means a used excavator can be adapted to many different types of jobs, increasing its value and utility on job sites.

To keep a used excavator operating at peak performance, regular maintenance is essential:

- Daily Inspections: Check fluid levels (engine oil, hydraulic fluid, coolant), inspect hydraulic hoses for leaks or damage, and monitor wear on tracks, rollers, and buckets.

- Lubrication: Ensure all pivot points, pins, and bushings are regularly greased to reduce friction and extend component life.

- Filter Replacements: Timely replacement of air, fuel, and hydraulic filters protects engine and system health, preventing contaminants from causing damage.

- Engine Tune-up: Periodic inspection and servicing to maintain fuel efficiency and power output.

- Undercarriage Care: Proper track tension and cleaning to remove debris that accelerates wear.

- Hydraulic System Checks: Monitor pressure and fluid cleanliness to avoid unexpected hydraulic failures.

- Attachment Inspection: Regularly assess all attachments for cracks, deformation, or wear, especially in high-stress components.

Adhering to a comprehensive maintenance schedule ensures a used excavator performs reliably, improves safety, and reduces expensive downtime, ultimately extending the machine's useful life.

In conclusion, excavators are incredibly versatile, powerful machines essential across multiple industries including construction, mining, forestry, agriculture, and infrastructure development. Their ability to dig, demolish, handle materials, and work in diverse environments makes them indispensable. The availability of used excavators offers businesses a cost-effective way to acquire reliable equipment with a proven track record, enabling enhanced productivity and project success without the financial burden of new machinery.

By thoroughly understanding the types, applications, attachments, and maintenance of excavators, businesses can choose the right machine that best suits their operational needs. For commercial vehicle suppliers like KeyChain Venture Co., Ltd., offering quality used excavators helps support customers around the world in achieving efficient, flexible, and economical worksite solutions.

When purchasing a used excavator, consider its hours of operation, maintenance history, engine and hydraulic system condition, attachment compatibility, and suitability for your specific tasks. Also, evaluate structural integrity, undercarriage wear, and overall machine appearance.

With regular maintenance and appropriate operation, a used excavator typically lasts between 8,000 to 12,000 operating hours. Factors such as the work environment, intensity, and operator skill impact lifespan.

Attachments are often compatible across models and brands, but always verify hydraulic pressure ratings, mounting connections, and control systems before interchange. Some adjustments may be needed to ensure proper fit and functionality.

Crawler excavators provide better traction, stability, and ground pressure distribution, making them ideal for soft, uneven, or muddy terrain. Wheeled excavators are more mobile on paved or hard surfaces but less stable on rough ground.

Proper maintenance prevents unexpected breakdowns, extends the life of wear parts, improves fuel efficiency, and reduces costly downtime and repair bills over the excavator's operational life.