Content Menu

● Introduction to Ore Excavation

● Why Choose Used Excavators for Ore Excavation?

>> Key Features of Used Excavators

● Preparing for Ore Excavation with Used Excavators

>> Equipment Inspection and Setup

● Step-by-Step Guide on How to Use Ore Excavation

>> Step 1: Positioning the Used Excavator

>> Step 3: Loading and Transporting

>> Step 4: Site Clean-up and Safety Checks

● Optimizing Ore Excavation Efficiency

● Using Technology in Ore Excavation

● Environmental and Safety Considerations

● Troubleshooting Common Issues with Used Excavators

● FAQ

>> 1. What are the benefits of using a used excavator for ore excavation?

>> 2. How do I maintain my used excavator for optimal ore excavation?

>> 3. Can used excavators handle hard rock excavation?

>> 4. What safety precautions should be taken during ore excavation?

>> 5. How do I select the best used excavator for my excavation project?

KeyChain Venture Co., Ltd., a leading commercial vehicle supplier in China, proudly offers cutting-edge solutions for passenger buses and heavy trucks domestically and globally. Understanding how to effectively use ore excavation techniques enhances operational efficiency in mining and construction projects where used excavators play a pivotal role. This comprehensive guide explores the best practices in ore excavation, focusing on the utilization of used excavators, supported by practical insights, multimedia references, and expert tips.

Ore excavation involves the removal of mineral-rich rock or soil from the earth to extract valuable ores for further processing. Efficient excavation is critical in mining operations to maximize ore recovery, reduce costs, and enhance safety. The choice of equipment is crucial; used excavators are versatile machines often favored due to their reliability and cost-effectiveness.

Ore excavation refers to the process of digging and transporting ore material from the mining site to processing areas. The methods vary depending on the ore's location, geology, and project scale. Excavators are central to these operations, helping miners achieve precision and speed.

Used excavators have gained popularity because they provide many advantages in mine site operations:

- Cost Efficiency: Used excavators offer high performance at a lower initial investment, ideal for budget-conscious projects.

- Proven Durability: Many machines maintain excellent working condition due to rigorous maintenance before resale.

- Availability of Parts and Services: Established brands guarantee availability of replacement parts and technicians worldwide.

- Versatility: Used excavators can adapt to various tasks based on attachment types, from digging trenches to loading ore onto trucks.

- Hydraulic systems for powerful digging

- Tailored attachments like buckets, breakers, and grapples

- Operator comfort for long shifts

- Robust undercarriage for rough terrain

Before starting excavation, proper preparation ensures smooth operations and maximizes safety.

- Analyze the terrain to determine soil and rock characteristics.

- Identify ore locations and depth using geological surveys.

- Plan the excavation route and equipment placement.

- Conduct thorough maintenance checks on the used excavator.

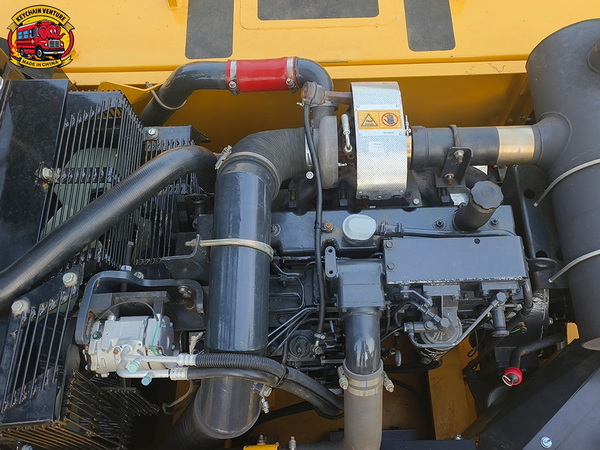

- Confirm hydraulic oil levels, engine condition, and track integrity.

- Attach appropriate tools based on ore type and excavation depth.

Proper positioning optimizes reach and stability.

- Select a firm, level base to avoid tipping.

- Orient the excavator for the most efficient digging arc.

- Ensure visibility and communication with truck operators.

- Use the bucket attachment to scoop ore material carefully.

- Avoid overloading or digging too deep in one pass.

- Rotate the boom smoothly to maintain precision.

- Load extracted ore into dump trucks or conveyors.

- Maintain proper weight distribution for transport safety.

- Coordinate with haulage schedules to avoid delays.

- Remove excess debris around excavation points.

- Inspect equipment for wear and damage.

- Follow safety protocols to protect workers and equipment.

Efficiency is vital to ensuring that ore excavation projects remain profitable and sustainable. Using a used excavator effectively requires maximizing machine uptime and productivity.

- Implement Real-Time Monitoring: Use tracking systems to monitor the excavator's operation, fuel consumption, and performance metrics.

- Operator Training: Invest in training programs to enhance operator skills, reducing wear and avoiding mechanical failures.

- Scheduled Maintenance: Prevent unplanned downtime by following manufacturer-recommended maintenance schedules and using high-quality oils and parts.

- Fuel Management: Optimize fuel use with planning and controlled idling, especially when running older used excavators.

- Load Management: Avoid overloading the excavator bucket to minimize strain on hydraulics and engine components.

Modern advances enhance the productivity and safety of ore excavation:

- GPS and Laser Guidance Systems: Provide accurate positioning and depth control, lowering material wastage.

- Remote Operation and Automation: Used excavators equipped with remote-control options allow operation in hazardous or difficult environments.

- Data Analytics: Mining companies can analyze excavator data to optimize cycles, reduce fuel consumption, and plan maintenance better.

- Drones for Site Survey: Aerial drones capture site topography and monitor excavation progress in real-time.

Sustainable mining practices increasingly demand attention to environmental impact and worker safety during ore excavation.

- Dust Suppression: Use water sprays and dust collectors to reduce airborne particulates.

- Noise Reduction: Operate excavators during designated hours and maintain mufflers to control noise pollution.

- Soil and Water Protection: Avoid contamination by carefully managing oil leaks and chemical spills.

- Worker Safety: Ensure all operators and nearby personnel wear personal protective equipment (PPE). Establish clear communication protocols and emergency procedures.

- Slope Stability: Monitor excavation angles to prevent landslides or collapses that could endanger workers.

Despite careful maintenance, challenges can occur during ore excavation.

- Hydraulic Leaks: Regularly check hoses and seals; replace deteriorated parts immediately.

- Track Slippage or Wear: Inspect the undercarriage frequently and adjust tensioning to extend life.

- Engine Stalling: Monitor fuel quality and perform regular engine diagnostics.

- Attachment Failure: Choose the right attachments for the material; ensure proper fitting to avoid detachment or damage.

- Operator Fatigue: Rotate operators and provide sufficient rest breaks to maintain focus and safety.

Utilizing used excavators in ore excavation presents a cost-effective, flexible, and reliable solution to mining challenges. By carefully selecting equipment, preparing the site, and following stepwise operational procedures, mining companies can significantly improve productivity while reducing operational costs. Integrating modern technologies, prioritizing safety, and maintaining equipment properly ensures long-term success and sustainability. KeyChain Venture Co., Ltd. remains committed to providing premier commercial vehicle solutions that support efficient mining operations worldwide.

Used excavators reduce capital expenditure while providing reliable, efficient performance suitable for various excavation conditions.

Regular inspections of hydraulics, engine oil, tracks, and attachments combined with timely repairs ensure high performance.

Yes, when fitted with rock breakers or reinforced buckets, used excavators can dig through hard rock efficiently.

Ensure equipment is stable, operators are trained, and communication between workers is clear to prevent accidents.

Assess your project needs for size, depth, and material type, then match with excavator specifications and available attachments.