Views: 222 Author: Amanda Publish Time: 2025-11-22 Origin: Site

Content Menu

● Understanding the Excavator: Key Components and Structure

● Why Start With a Used Excavator?

● Pre-Operation Checklist for Safety and Efficiency

● Entering the Cab and Getting Comfortable

● Starting Up: Bringing the Machine to Life

● Learning the Controls: Joysticks and Pedals

● Safe Movement and Positioning on Site

● Foundation Skills: Digging, Loading, and Dumping

● Advanced Tasks: Grading, Backfilling, and Trenching

● Routine Maintenance for Longevity

● Developing Professional-Level Efficiency

● Choosing and Maintaining a Used Excavator: Key Considerations

● FAQ

>> 1. How do I choose the right size Used Excavator?

>> 2. Is there a big difference in controls between new and Used Excavators?

>> 3. What regular maintenance should I perform on a Used Excavator?

>> 4. How can I ensure job site safety as a beginner?

>> 5. Where can I find reliable Used Excavators for training or work?

Operating an excavator as a beginner brings the promise of mastering a versatile and powerful piece of heavy equipment, essential in both construction and landscaping. Opting for a Used Excavator is an economical step that offers flexibility and ample learning opportunity with the added bonus of a lower investment threshold. This comprehensive guide is designed to help first-time operators and potential buyers unlock the practical skills, foundational knowledge, and maintenance insights needed to achieve both safety and efficiency on the job site.[2][6]

An excavator, whether new or used, consists of carefully designed elements that combine to provide strength, reach, and efficiency. The main components include:

- Cab: The enclosed area providing operator controls, safety, and comfort.

- Upper Structure: Houses the engine, hydraulic pumps, and counterweight, capable of a 360° rotation atop the undercarriage.

- Undercarriage: Equipped with tracks or wheels for mobility and stability on all terrains.

- Boom, Stick (Dipper), and Bucket: The articulated arm and bucket perform digging, loading, and lifting tasks.

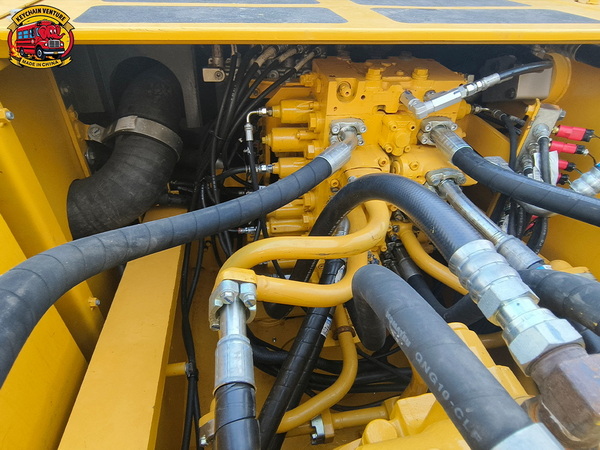

- Hydraulic System: Enables powerful, precise movement of the arm and attachments.[7]

When buying or using a Used Excavator, it's vital to inspect these parts for wear, leakage, or structural damage before starting operation.[6]

A Used Excavator allows new operators or small businesses to access capable machinery without the upfront cost of a new model. Used machines offer:

- Lower acquisition cost

- Proven reliability if sourced from a reputable dealer

- Flexibility to train and experiment without substantial depreciation risk

- Continued utility with proper maintenance

A Used Excavator, when carefully inspected and maintained, delivers significant performance for various site tasks—from digging trenches to material handling—making it an excellent starting point for beginners.[7]

Conducting a methodical pre-start check prevents most common operating issues and keeps both operator and machine safe.

- Hydraulic Fluid and Oil Levels: Refill as required and check for fluid leaks beneath the machine.[6]

- Tracks and Undercarriage: Look for rocks, packed mud, or wear on rollers and sprockets.

- Bucket, Pins, and Linkages: Ensure these are well-greased and free from cracks or unusual play.

- Safety Equipment: Verify that seatbelts, handrails, mirrors, and decals are present and in good condition.

- Control Levers and Gauges: Confirm that all controls operate smoothly and that emergency switches/warnings are functional.[5]

A Used Excavator should be examined for signs of previous repairs. Non-factory welds, mismatched paint, or worn decals indicate areas requiring closer attention before use.[6]

Use three points of contact when entering the operator's cab. Adjust the seat and armrests for comfort during extended shifts. Familiarize yourself with:

- The instrument panel (fuel, temperature, hydraulic warnings)

- Boom, stick, bucket, and swing controls on the joysticks

- Travel pedals/levers for maneuvering tracks

- The safety lock lever, which disables hydraulic movement when raised[5]

On a Used Excavator, minor differences in control layout or responsiveness due to age are expected, so take time to adjust before starting work.[6]

With both safety and hydraulic locks engaged:

- Insert the key and start the engine, letting it idle for several minutes—particularly in cooler weather or when dealing with an older Used Excavator—so oil and hydraulic fluid reach suitable temperature and pressure.[4][6]

- Observe the control panel; warning lights or abnormal readings should be addressed before disengaging locks.

- Listen for any strange noises from pumps or engine that could suggest mechanical issues.

Once the system is stable, release the safety lock to empower the hydraulic controls. You are now ready to begin basic maneuvering.

Excavator controls use standardized patterns (ISO or SAE) but may differ between models. Always review the control guide for your specific machine.

- Left Joystick: Up/Down—Swing boom left/right; Left/Right—Move stick out/in

- Right Joystick: Up/Down—Raise/lower boom; Left/Right—Curl/uncurl bucket[1][3][5]

- Travel Levers/Pedals: Forward or reverse individual tracks, enabling turning or straight-line movement

When practicing on a Used Excavator, move controls slowly, as response time may differ from newer models due to minor hydraulic wear. Develop coordination by excavating in slow, deliberate cycles before progressing to more advanced digging.[6]

Mastering site movement with a Used Excavator is essential for both productivity and safety.

- Align tracks straight before moving, keeping the heavier boom towards travel direction for better stability.

- Move slowly; avoid sudden turns or changes in terrain that may stress the undercarriage.

- Always check your surroundings using mirrors and windows: never swing or travel without confirming a clear path.[4]

- Avoid driving across steep slopes; travel straight up or down inclines.

A Used Excavator with a well-maintained undercarriage handles movement effectively, but beginners should be especially cautious on wet, muddy, or uneven surfaces.

Excavator work cycles can be broken down into fundamental steps:

1. Digging:

- Lower the boom and extend the stick.

- Position the bucket teeth at the planned start point.

- Pull the stick inwards while curling the bucket to load material without overfilling—this improves control and minimizes spillage.

2. Swinging:

- Rotate the cab towards the deposition point using the joystick.

- Practice smooth, gradual swings, especially important with a Used Excavator for consistent load handling.[4]

3. Dumping:

- Raise the boom enough to avoid obstacles.

- Extend the stick and uncurl the bucket to precisely deposit soil or debris.

Return the arm to the dig area to repeat the cycle. Beginners should practice these moves slowly and with partial loads until they are comfortable synchronizing all actions smoothly.[5][6]

Beyond simple digging, excavators—especially robust Used Excavators—are capable of more nuanced earthmoving.

- Grading: Use the bucket's underside to smooth surfaces, feather the controls for shallow, even layers, and avoid “gouging” the ground.

- Backfilling: After laying pipes or foundations, use the excavator to push soil into trenches in layers, compacting gently after each pass.

- Trenching: For straight, uniform trenches, align the cab and undercarriage, work from the farthest end back towards yourself, and use the stick to maintain consistent depth.[4]

Building advanced skills on a Used Excavator requires patience, but with time and repetition, operators achieve precision matching that of any modern machine.

Beginner operators should prioritize safety above all else.

- Never carry passengers on the machine.

- Always use the seatbelt and keep cab doors and windows properly closed during operation.

- Maintain clear, established communication with ground personnel, especially when scheduled for work around overhead wires or underground utilities.

- When parking a Used Excavator, lower the attachment to the ground, set the parking brake, and engage the hydraulic lock before exiting.[5]

Accidents often result from overlooked basics. Consistently applying safety procedures reduces equipment damage and protects everyone onsite.

Maintenance is especially crucial for Used Excavators. Performing daily checks, periodic fluid replacement, and scheduled part inspections help prevent breakdowns and maintain performance:

- Grease all pins and bushings as recommended; clean dirt or debris from moving joints.

- Check the tracks for proper tension and alignment.

- Clean or replace air filters at required intervals to protect the engine.[6]

- Retain a service log noting work hours, maintenance performed, and any observed issues. This record supports improved operating practices and higher resale value in the future.

With these practices, even an older excavator will deliver strong, reliable performance for years.

As skills progress, focus on efficiency:

- Plan digging cycles in advance; position trucks or stockpiles to reduce unnecessary swinging and travel.

- Practice “feathering” controls for gentle, precise movement rather than abrupt starts and stops.

- Gradually increase bucket fill and swing speed as confidence builds.

- Learn to use grade-control systems or set out reference markers for consistent results—especially valuable when using a Used Excavator lacking digital features.[4]

Continued learning, whether through hands-on experience, formal operator courses, or equipment manuals, will raise performance to professional levels.

Selecting a Used Excavator starts with assessing job requirements (size, reach, capacity) and ends with diligent inspection and testing. Buy from reputable sellers offering maintenance records, full inspections, and after-sales support.

Keep these factors in mind:

- Match machine size to intended project.

- Inspect engine, hydraulics, and undercarriage for excessive wear.

- Test all controls and observe operational smoothness.

- Inquire about prior repairs and perform a field test before purchase.[7][6]

With ongoing care, a Used Excavator is a lasting asset for projects ranging from landscaping to earthmoving.

Learning how to use an excavator as a beginner opens a pathway to a rewarding and versatile heavy equipment skill set. Choosing a Used Excavator combines cost-effectiveness with real-world experience, offering a practical training ground for new operators. By mastering key checks, control routines, excavation techniques, and safety practices, anyone can confidently leverage the capabilities of these indispensable machines.

Through professional maintenance, patience, and continuous skill development, Used Excavators not only meet standard job site demands but can also become central assets for efficient earthmoving and construction operations. As your experience grows, so too does your ability to maximize productivity and ensure safety in every task.

Start by assessing the type of work—site access, expected trench depth, lifting needs, and attachment options. A compact Used Excavator works well for tight sites, while a standard or large unit is better for major earthmoving.[7]

The key control principles remain the same, although Used Excavators may have slightly older layouts or less sensitive hydraulics. Always spend time practicing on the machine you'll use.[6]

Check and top up fluids, grease pins and bushings, inspect tracks, clean air filters, and keep a maintenance log. Address issues promptly to avoid breakdowns.[6]

Always conduct a walk-around inspection, use proper PPE, establish clear communication with coworkers, follow site rules, and never allow unauthorized passengers or distractions in the cab.[5]

Work with established equipment dealers or rental companies that offer support, clear maintenance histories, and post-sale assistance. KeyChain Venture Co., Ltd. is a trusted source in China and worldwide.

[1](https://www.youtube.com/watch?v=uutTJgY7Br0)

[2](https://dozr.com/blog/how-to-operate-a-mini-excavator)

[3](https://www.youtube.com/watch?v=oE8nB2QGFBo)

[4](https://www.sanyglobal.com/blog/how-to-operate-excavator/)

[5](https://heavyequipmentcollege.edu/how-to-operate-an-excavator/)

[6](https://www.stockyard.supply/blog/how-to-operate-a-mini-excavator-like-a-pro-tips-tricks)

[7](https://ahmcorp.com/blogs/news/the-compact-excavator-a-complete-guide-for-beginners)

[8](https://www.steeltoeu.com/blog/part-1-how-to-run-an-excavator-for-beginners-what-you-need-to-know-to-get-started)

[9](https://www.youtube.com/watch?v=kUs6G5iBGP0)

[10](https://www.reddit.com/r/heavyequipment/comments/1orz9de/how_do_i_learn_how_to_operate/)

Field Visit To DR Congo – Products in Action, Friendships in Progress

Treat Your Team to the Perfect Ending: A Cultural Day & Rejuvenating Massage

Just received this absolutely gorgeous bouquet specially ordered by our lovely customer!

Truly inspiring conversations today with our highly insightful client!

Today, we visited the bus company together with our client. It was really wonderful!

A Milestone Moment: Custom Buses Successfully Shipped, Setting Course for New Horizons

Forging Stronger Ties: Welcoming Key African Partners to Chongqing for Transport Collaboration