Views: 222 Author: Amanda Publish Time: 2025-08-21 Origin: Site

Content Menu

● Advantages of a Used Excavator

● Preparing to Use a Mini Excavator

>> 2. Review the Operating Manual

● Mini Excavator Controls Explained

● Step-by-Step Guide to Operating a Mini Excavator

>> Step 1: Mount the Machine Safely

>> Step 3: Unlock the Safety Lock

>> Step 4: Practice Basic Movements

>> Step 6: Travel and Maneuver

>> Step 7: Parking and Shutdown

● Safety Tips When Using a Mini Excavator

● Common Applications of Mini Excavators

● Maintenance Tips for Longevity

● FAQ

>> 1. What should I check before using a used excavator?

>> 2. How can I improve digging precision with a mini excavator?

>> 3. Can I use a mini excavator on paved surfaces?

>> 4. What is the average lifespan of a used excavator?

>> 5. Are specific trainings needed to operate a mini excavator?

Mini excavators have become indispensable tools in the construction and landscaping industries, especially for projects requiring precision, maneuverability, and efficiency in confined spaces. Whether you are a seasoned operator or new to heavy equipment, understanding how to use a mini excavator correctly and safely is key. This comprehensive guide covers everything from preparation and controls to operation techniques and maintenance, ensuring you get the most out of your mini excavator. Emphasizing the advantages of a used excavator, this article helps you optimize your investment and improve productivity.

A mini excavator is a compact, versatile construction machine typically weighing between 1 to 10 tons. Unlike full-size excavators, mini excavators are designed to operate efficiently in tight spaces without compromising digging power or precision. Their small footprint, combined with a range of attachments such as buckets, breakers, and grapples, makes them popular across various sectors, from residential landscaping to urban construction.

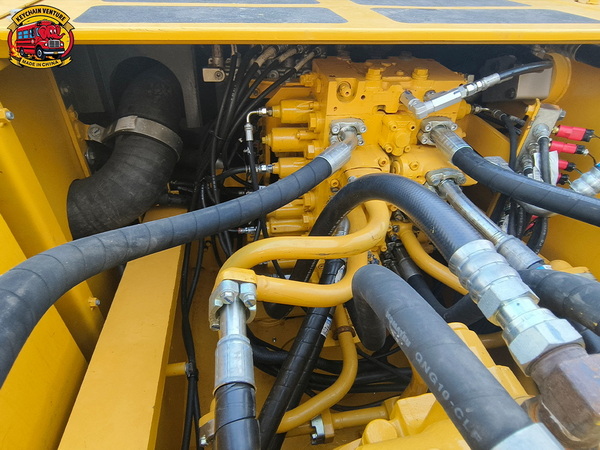

Mini excavators use a hydraulic system to operate the boom, arm, and bucket. Their tracked undercarriage allows for excellent stability and traction on uneven terrain. Given their size and versatility, mini excavators are ideal for tasks such as trenching, demolition, site clearing, and material handling.

If you're considering purchasing a machine, a used excavator offers you the flexibility to own reliable machinery at a more economical price point, a fact that has made them especially attractive in the construction equipment market.

Purchasing a used excavator can be a smart choice for businesses or individuals looking to invest in efficient machinery without breaking the budget. Key advantages include:

- Cost-Effective: Used excavators typically cost less than new models, reducing upfront investment. This benefit is crucial when managing the capital expenditure of a construction project or when expanding a fleet economically.

- Proven Reliability: Many used machines come with a documented maintenance history ensuring dependable performance. When sourced from reputable suppliers, used excavators can maintain exceptional working conditions.

- Faster Availability: Unlike new orders that have lead times, used excavators are typically available immediately, critical for urgent project requirements.

- Wide Selection: There's a broad market of used excavators for sale, allowing buyers to choose models that perfectly match their needs, from mini excavators suitable for compact urban environments to heavy-duty models for large projects.

- Depreciation Benefits: New machines depreciate quickly in the first few years. By buying used, you avoid this initial loss, retaining better equipment value over time.

Choosing a used excavator, especially from trusted vendors, combines cost savings and performance, ideal for companies that seek to maximize ROI.

Before starting operation, proper preparation enhances safety and machine longevity:

- Check engine oil, hydraulic fluid, and coolant levels. Low or dirty fluids can severely damage the machine.

- Inspect tracks and undercarriage for cracks, damage, or excessive wear. Track misalignment can affect stability and cause accidents.

- Verify all controls, levers, and safety features work correctly including emergency stop and horn.

Familiarize yourself with your model's specific controls, recommended operating procedures, load limits, and maintenance schedules. Manuals often contain vital troubleshooting tips.

Ensure the working area is free of debris, obstacles, and underground utilities. Mark any hidden hazards to avoid accidental damage during excavation.

Personal protective equipment (PPE) such as hard hats, gloves, steel-toed boots, and high-visibility vests are essential to protect against job site hazards. Ear protection may be necessary for long hours of operation.

Establish clear goals and digging patterns before starting the machine. This helps reduce unnecessary movements that waste fuel and cause wear.

Understanding the controls is vital for efficient operation:

Joysticks:

- Left joystick controls the boom's vertical movement and the swing (rotation of the upper structure).

- Right joystick controls the stick's in and out movement and bucket curl or dump function.

Travel Pedals or Levers:

- Used to move the mini excavator forward, backward, and steer left or right by operating individual tracks. Some models allow skid steering for sharp turns within tight spaces.

Throttle Control:

- Adjusts the engine speed enabling harsher digging or slower, more controlled movements.

Safety Lock Lever:

- Locks hydraulic functions to prevent accidental activation when moving or during maintenance.

Auxiliary Controls:

- For managing attachments such as hydraulic breakers, grapples, or augers, essential for versatile task execution.

Familiarity with these controls reduces the learning curve and minimizes operational errors, especially when handling a used excavator that may have slight operational differences compared to brand-new models.

Always enter the cabin using the designated steps and handles, maintaining three points of contact to avoid slips or falls.

Engage the safety lock lever before starting. Turn the ignition key and allow the engine to warm up for several minutes, especially in cold weather, to ensure optimal hydraulic fluid flow and engine performance.

Disengage the safety lock once you're seated comfortably and ready to operate. Now the hydraulic controls become active.

Begin by slowly moving the boom up and down, swinging the house left and right, extending and retracting the arm, and curling or dumping the bucket. Become comfortable with the joystick sensitivity.

- Position the mini excavator as close as possible to the digging area to maximize reach and control.

- Lower the boom carefully and extend the arm out towards the soil.

- Curl the bucket to scoop the earth and pull it toward the machine.

- Lift the bucket out of the trench and swing to dump the soil securely aside, ensuring no damage to surroundings.

Use the travel pedals or levers for smooth forward or backward motion. To turn, apply more force to one track causing the excavator to pivot—a skill crucial for navigating tight spaces commonly faced in urban projects.

Once work is complete, park the mini excavator on a level surface, lower the attachments fully, engage the safety lock, and switch off the engine. Conduct a brief post-operation inspection to check for any issues.

Heavy equipment operation always involves risk. Implement these best practices for safety:

- Conduct a thorough pre-operation inspection every day.

- Keep a safe distance from excavation edges to avoid collapse risk.

- Ensure the machine's roll-over protective structure (ROPS) and seatbelt are functional and used at all times.

- Never operate the mini excavator when fatigued or under the influence.

- Avoid swinging the bucket over people or vehicles.

- Be alert to underground utilities and always consult utility maps before digging.

- When working near traffic or pedestrians, use barriers, signage, and a trained spotter to manage site safety.

A used excavator may require extra attention due to wear; regularly inspect critical safety components like brakes and hydraulic hoses.

Mini excavators are highly versatile, with applications across multiple sectors:

- Landscaping: Ideal for trenching irrigation lines, removing small trees or stumps, and site grading. Precision and low ground impact help preserve delicate surroundings.

- Construction: Used extensively for digging foundations, installing underground utilities such as water and electrical lines, and clearing construction debris.

- Agriculture: Useful for creating ditches, digging post holes, or reshaping terrain for farming operations.

- Demolition: Small-scale demolition can be handled efficiently using breakers or grapples attached to a mini excavator's hydraulic system.

- Material Handling: Loading soil, gravel, or other materials for transport, as well as moving debris on sites.

Attachments such as hydraulic hammers, augers, and tilt buckets greatly expand the utility of mini excavators, making the investment valuable, especially when purchasing a used excavator equipped with compatible accessories.

Consistent maintenance prevents costly repairs and machine downtime:

- Change engine oil and hydraulic fluid according to manufacturer recommendations. Dirty fluid reduces efficiency and causes wear.

- Inspect and tighten track tension regularly – too loose or too tight can damage components and affect stability.

- Clean the undercarriage frequently to remove mud, rocks, and debris that can accelerate wear of rollers and sprockets.

- Grease all pins and moving joints to prevent corrosion and wear.

- Check hydraulic hoses for leaks, cracks, or signs of deterioration, especially important on older used excavators.

- Test all controls and safety systems before and after each use.

- Store machinery in dry, sheltered areas to reduce exposure to weather that accelerates rust and electronic component failure.

Preventive maintenance extends the service life of both new and used excavators, ensuring that even older machines perform with near-new reliability.

Learning how to use a mini excavator proficiently can transform your workflow on various construction, landscaping, or agricultural projects. Choosing a used excavator balances operational efficiency with cost savings, helping businesses scale or equip projects affordably without sacrificing quality. Detailed preparation, control familiarity, adherence to safety guidelines, and diligent maintenance form the foundation of safe and effective mini excavator operation. With experience and care, your mini excavator will become an invaluable asset delivering precision work and long-term performance.

Always inspect fluid levels (engine oil, coolant, hydraulic fluid), track condition, hydraulic hoses, and all controls for smooth, responsive operation. Verify the maintenance history if possible.

Smooth joystick operation, steady positioning, and using the right bucket size are key. Practice control movements regularly to enhance accuracy.

Yes, but using rubber tracks is recommended to avoid damaging asphalt or concrete surfaces.

With proper maintenance, used excavators often last over 10,000 hours, but lifespan depends on model, usage, and upkeep quality.

Most regions require operators to be trained or certified. Professional courses improve safety and efficiency, essential for commercial operations.