Views: 222 Author: Amanda Publish Time: 2025-09-08 Origin: Site

Content Menu

● Introduction to Excavator Fuel Consumption

● Factors Affecting Fuel Usage of Excavators

>> Engine Power and Efficiency

● Average Fuel Consumption of Different Excavator Types

● Comparison Between New and Used Excavators' Fuel Efficiency

● Tips to Reduce Fuel Consumption in Excavators

>> 1. Maintain Regular Service

>> 2. Avoid Prolonged Idle Time

>> 3. Train Operators for Efficiency

>> 4. Select Proper Machine Size for the Job

>> 5. Use Fuel Monitoring Systems

>> 6. Plan the Worksite Layout and Cycle Times

>> 7. Use Idle Management Technologies

>> 8. Upgrade to Fuel-Efficient Components

● Environmental Impact of Excavator Fuel Usage

● Frequently Asked Questions (FAQ)

>> 1. How much fuel does a used excavator typically consume per hour?

>> 2. Can I improve the fuel efficiency of a used excavator?

>> 3. What factors most influence an excavator's fuel consumption?

>> 4. Are newer excavators always more fuel efficient than used ones?

>> 5. How does fuel consumption affect the total cost of owning an excavator?

Excavators are essential machines in the construction, mining, and heavy-duty industries. Understanding how much fuel an excavator uses is crucial for project planning, cost estimation, and environmental impact management. As a leading commercial vehicle supplier, KeyChain Venture Co., Ltd. offers high-performance solutions, including used excavators that provide excellent efficiency. This article explores in detail the factors influencing excavator fuel consumption, typical usage rates, tips for reducing fuel use, and much more.

Excavators, being powerful heavy machines, depend on diesel fuel to perform various tasks such as digging, lifting, and loading materials. Fuel cost is one of the highest operational expenses in the lifecycle of an excavator. Whether you are considering purchasing a used excavator or upgrading your current fleet, understanding fuel consumption is vital.

Fuel consumption depends on multiple parameters like engine size, operating conditions, load, and operator expertise. For businesses using heavy equipment regularly, even small efficiencies can translate into significant cost savings and reduced emissions.

Excavators operate in many environments—from urban construction sites to rough terrain in mining operations. The intensity and frequency of their usage directly impact the fuel they consume. For instance, an excavator working continuously in a heavy digging project will use much more fuel than one performing light excavation or site cleanup.

Several factors influence the amount of diesel fuel an excavator consumes, including:

The size of an excavator is perhaps the most straightforward factor that affects fuel consumption. Small compact excavators consume substantially less fuel than large mining or heavy-duty models. Mini-excavators might consume around 2 to 4 gallons per hour, whereas large hydraulic excavators involved in mining or large construction projects can easily consume over 15 gallons per hour.

The type of excavator also plays a significant role. For example, standard hydraulic excavators, long reach excavators, and crawler excavators each have different fuel demands based on their designs and applications.

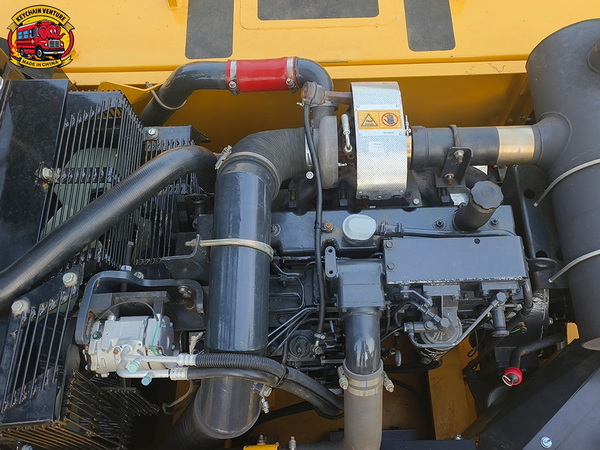

A high-powered engine usually means higher fuel consumption, but modern engines balance power and efficiency effectively. Excavators built with newer engine technology often feature fuel-saving capabilities like automatic idle shutdown, variable engine speeds, and advanced fuel injection systems, which can reduce consumption by up to 20%.

Used excavators, especially those older models, generally consume more fuel due to engine wear, outdated technology, or poor maintenance. However, some used excavators can be reconditioned or retrofitted with improved components to enhance their fuel efficiency.

Fuel consumption varies considerably with operating conditions. Continuous heavy-duty digging, lifting, or loading requires more fuel than trenching or light grading. Similarly, working on uneven, rocky, or hilly terrain stresses the machinery more than flat, smooth sites. Extreme weather conditions like very cold or hot climates also influence fuel consumption as the engine works harder to maintain performance.

Operator behavior can have a surprising impact on fuel use. Skilled operators who reduce idle times, avoid rapid movements, and optimize digging cycles can reduce fuel consumption significantly. Conversely, inexperienced or careless operators may waste fuel with unnecessary idling, rough operation, or inefficient machine handling.

Operator training is an often-overlooked investment that can maximize return on both new and used excavators by cutting fuel costs and extending equipment life.

Proper maintenance keeps the machine running efficiently. Neglected maintenance may cause clogs in the fuel system, dirty air filters, or worn-out hydraulic fluids, all of which increase fuel consumption. For used excavators, regular maintenance is critical to retain fuel efficiency and avoid escalating operational costs.

Scheduled maintenance, such as oil changes, filter replacements, and hydraulic system checks, ensures that the engine and related systems operate under optimal conditions.

The weight of the materials being moved and the speed of operations influence fuel usage. Higher loads demand more engine power and thus, more fuel. Similarly, faster cycle times with quick lifts and rapid bucket movements increase fuel usage compared to slow, deliberate work cycles.

Planning work tasks to avoid unnecessary heavy lifting or excessive speed can help control fuel consumption.

Fuel usage varies widely based on the excavator's capacity and intended application. In general terms:

- Mini Excavators (1-2 tons): These smaller machines typically consume between 1.5 to 3 gallons of diesel per hour. Ideal for small jobs such as residential landscaping or utility trenching, they offer low fuel usage due to their compact size and less powerful engines.

- Medium Excavators (5-10 tons): Used commonly in urban construction or roadwork, these excavators usually use between 4 to 8 gallons of fuel per hour. Their size allows for a balance of power and efficiency suitable for most mid-range tasks.

- Large Excavators (20+ tons): These machines are employed in heavy construction, infrastructure, and mining projects, consuming between 10 to 20 gallons per hour or more. Their powerful engines and robust components make them fuel-hungry but essential for large-scale work.

- Ultra Large Mining Excavators: The biggest excavators used in mining and large earthmoving projects can consume over 20 gallons per hour. These machines are specialized, and fuel costs represent a significant portion of total operating expenses.

A used excavator typically falls within these ranges but may lean toward higher fuel consumption depending on age and condition. It is always advisable to check fuel consumption during inspections of used equipment to estimate ongoing operational costs accurately.

When deciding to purchase either a used excavator or new equipment, fuel efficiency is a key concern:

- Feature the latest engine technology that meets current emission and efficiency standards.

- Often benefit from improved hydraulic systems, enhanced electronic controls, and telematics that provide real-time fuel monitoring.

- Usually come with warranties and service packages that help maintain optimum performance.

- Generally offer a lower initial purchase price, which can be attractive for businesses, but may have higher fuel consumption due to older engine models or wear.

- Their fuel efficiency largely depends on their maintenance history and how heavily they were used.

- They can still be a good investment if inspected thoroughly and well maintained, especially if you want to expand capacity without high capital costs.

In many cases, it is beneficial to balance upfront cost savings from buying a used excavator with potential higher fuel expenses. Today's used excavator market is robust, and better-maintained machines with updated parts can perform efficiently with good fuel economy.

Maximizing fuel efficiency is critical, especially when operating multiple excavators or working on long-term projects. Here are practical tips for reducing fuel consumption:

Ensure all filters and fluids are clean and changed on schedule. Well-lubricated hydraulics and a tuned engine help reduce wasted fuel.

Excavator engines consume significant fuel when idling. Use automatic idle shutdown systems if available or encourage operators to switch off engines during extended breaks.

Smooth digging, minimizing rapid acceleration or unnecessary swinging of the boom, and planning effective working cycles all reduce fuel waste.

Using an oversized excavator for simple, light work causes excessive fuel consumption and impacts costs negatively.

Install or utilize telematics that track fuel use to detect inefficiencies or sudden increases that may indicate mechanical issues.

Reducing travel distance between dig sites and avoiding frequent stops and starts cuts fuel use.

Many newer and some retrofitted used excavators include idle management technology that adjusts engine speeds automatically to reduce fuel consumption.

Where possible, replacing worn parts with newer, fuel-saving technologies can help, especially for used excavators.

The cumulative effect of these practices can result in significant fuel savings, lowering operational expenses and environmental footprint.

Beyond cost, fuel consumption impacts the environment. Diesel combustion in excavator engines releases greenhouse gases including CO2 and pollutants like NOx and particulate matter. Reducing fuel use on excavators contributes to cleaner air and helps meet increasingly strict environmental regulations.

- Adoption of hybrid, electric, or alternative fuel excavators is growing, though diesel machines remain dominant globally.

- Retrofitting used excavators with emission control devices can enhance environmental performance.

- Businesses committed to sustainable operations monitor and manage fuel consumption carefully to reduce carbon footprints.

Efficient fuel use not only lowers costs but also supports eco-friendly construction and mining practices, reinforcing corporate social responsibility goals.

Understanding how much fuel an excavator uses is essential for effective fleet management, cost control, and environmental stewardship. Excavator fuel consumption varies significantly depending on machine size, engine technology, operating conditions, operator skills, and maintenance. Both new and used excavators can offer efficient and powerful solutions, but attention to fuel efficiency is vital in either case.

At KeyChain Venture Co., Ltd., we provide a comprehensive range of high-performance used excavators engineered for durability and fuel efficiency. By selecting the right machine and adopting best practices in operation and maintenance, you can optimize fuel consumption, reduce costs, and minimize environmental impact across your projects.

Used excavators typically consume between 4 to 15 gallons per hour, depending on the machine's size, age, and operating conditions. Smaller used excavators consume less, while large models consume more.

Absolutely. Regular maintenance, proper tuning, operator training, minimizing idle time, and using fuel-efficient working techniques can enhance the fuel efficiency of used excavators significantly.

The main factors are excavator size, engine condition, operating load, terrain, operator behavior, and maintenance status. Each can impact fuel use differently depending on the job at hand.

Generally, newer excavators are designed with advanced fuel-saving technologies and meet stricter emission regulations. However, a well-maintained used excavator can perform efficiently with proper upkeep and operation.

Fuel expenses often form a large part of total operational costs for excavators. More efficient fuel use directly lowers operating expenses and improves the profitability of construction projects.