Views: 222 Author: Amanda Publish Time: 2025-08-21 Origin: Site

Content Menu

>> Common Uses of Excavators Include:

>> Popular Types of Excavators:

● Licensing Requirements for Excavator Operators

● Using a Used Excavator: Legal and Safety Concerns

● Alternatives to Licenses: Certifications and Training

● Risks of Operating an Excavator Without a License

● How to Get Licensed to Operate an Excavator

● Tips for Buying and Operating a Used Excavator

>> Buying Tips:

● FAQs

>> 1. Do I need a license to operate a used excavator on private land?

>> 2. Can I rent a used excavator without a license?

>> 3. What is the difference between a license and a certification for excavator operators?

>> 4. How often do I need to renew my excavator operator license?

>> 5. Are there any exceptions for small or mini excavators?

Operating heavy machinery like an excavator is critical in many industries such as construction, landscaping, and mining. If you're considering using an excavator, especially a used excavator, you might wonder: Can you use an excavator without a license? This article comprehensively explores the legal, safety, and practical considerations relating to using an excavator without formal licensing, the types of permits required in different regions, and how to safely operate a used excavator whether you hold a license or not.

Excavators are vital pieces of construction machinery used for digging, demolition, grading, and material handling. The demand for used excavators continues to grow due to their cost efficiency and reliability. However, the question of whether an operator needs a license to operate these machines is common and important.

In many jurisdictions, the answer depends on local laws, the context of use, and the machinery size. This article sheds light on these factors and is essential reading for anyone planning to operate an excavator, especially a used excavator. Throughout this guide, we incorporate practical insights, visual aids, and video demonstrations to provide a well-rounded understanding.

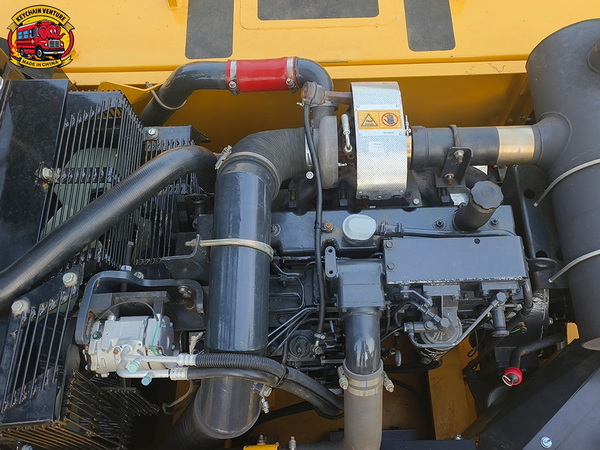

An excavator is a tracked or wheeled heavy equipment machine commonly used for excavating or moving large objects. It consists of a boom, stick, bucket, and cab on a rotating platform. Excavators come in various sizes, from mini excavators to large hydraulic mining excavators.

- Digging trenches and foundations

- Demolition

- Forestry work

- Mining

- Material handling and lifting heavy loads

- Mini Excavators: Compact and versatile for light tasks

- Standard Excavators: Mid-sized, suitable for most construction work

- Long Reach Excavators: Extended boom for deep digging or hard-to-reach areas

- Crawler Excavators: Equipped with tracks, ideal for rough terrain

Because of their versatility and power, excavators are indispensable on construction sites, making operator competence vital.

Operating an excavator often requires specialized skills and knowledge to ensure safety and efficiency. Many countries and regions have regulations dictating whether operators need formal licenses or certifications.

- United States: Licensing is not federally mandated but OSHA (Occupational Safety and Health Administration) requires operators to be trained and certified for heavy equipment use on construction sites. Many states and employers enforce their own operator certification programs.

- United Kingdom: Operators must typically possess a CPCS (Construction Plant Competence Scheme) card to operate an excavator legally on most construction projects. The CPCS ensures operators have passed health and safety and practical competency tests.

- Australia: Licensing requirements vary by state; some states demand formal high-risk work licenses for operating excavators above a certain capacity, especially those over 10 tonnes. Queensland and Victoria have specific requirements governed by WorkSafe agencies.

- China: Licensing or certification is required, particularly for large heavy equipment operators, ensuring compliance with safety standards. The regulations emphasize operator training and examination before granting permission to operate machinery like excavators.

These licensing frameworks typically aim to prevent accidents and encourage professional competence when operating heavy machinery.

When purchasing or using a used excavator, additional factors come into play regarding legal operation and safety.

- Ownership and registration status: Verify that the used excavator has clear ownership, proper documentation, and is eligible for operation according to local transportation or construction authorities.

- Compliance: Ensure the excavator meets current emission standards and safety regulations, as older machines may require upgrades or inspections before use.

- Seller Credentials: Request maintenance and operation histories to avoid buying equipment with hidden damages or previous accidents that may compromise safety.

Failure to meet these requirements can result in legal penalties, fines, or forced suspension of the excavator usage.

- Mechanical Condition: Older excavators might have worn hydraulic components, brake issues, or electrical faults. It's important to conduct detailed mechanical inspections and possibly testing by qualified technicians.

- Proper Maintenance: Establish a strict maintenance schedule to ensure reliability after purchase. Neglected maintenance can cause breakdowns and safety hazards.

- Operator Familiarization: Using a used excavator with different controls or configurations than newer models necessitates operator training to prevent costly errors or accidents.

Owning a used excavator does not exempt you from needing a license or proper training if local laws require it. Moreover, regardless of licensing, safety must always take precedence when using heavy machinery.

In cases where a formal license is not mandatory by law, many employers and contractors still require evidence of adequate training and certification.

- OSHA Certified Training Programs: OSHA offers courses for heavy equipment operators that cover safety, hazard recognition, and machinery operation best practices.

- Manufacturer-Specific Operator Training: Brands such as Caterpillar, Komatsu, and Hitachi provide training programs tailored to their equipment, including used excavators that may come with unique features.

- Safety Training Seminars and Short Courses: Industry associations and private training centers offer certification courses focusing on excavation safety, signaling, and emergency response protocols.

- Enhances operator safety skills and reduces accident risk

- Boosts operational efficiency by teaching best practices and proper machine handling

- Builds credibility and employability for operators

- Often mandated by major contractors or rental companies

Even if a license is not strictly required, obtaining certifications can make a substantial difference in safety and performance.

Operating an excavator without proper licensing or training carries significant risks including:

- Increased Accident and Injury Risk: Excavators are heavy and powerful machines; improper use can lead to severe injuries or fatalities on site. Unlicensed operators may lack knowledge of key safety practices.

- Legal Penalties and Fines: Many jurisdictions impose fines, suspension, or even criminal charges on employers and individuals who violate heavy equipment operation laws.

- Voiding of Insurance Claims: In the event of an accident, insurance companies may reject claims if the operator is not licensed, leaving companies liable for damages and compensation.

- Damage to Equipment or Property: Incorrect operation can cause costly equipment failures, structural collapse, or environmental damage. The financial consequences can be substantial, especially when repairing or replacing a used excavator.

- Work Delays: Accidents, machine breakdowns, and legal repercussions can delay projects, impacting timelines and profitability.

Becoming a licensed excavator operator typically involves a combination of training, written exams, and practical demonstrations.

1. Enroll in a certified heavy equipment operation school or program: Many vocational schools, unions, and training centers offer comprehensive courses tailored to excavator operation.

2. Complete classroom and hands-on training sessions: Courses usually cover equipment controls, site safety, hazard recognition, and basic mechanical troubleshooting.

3. Pass written and practical exams: These tests assess knowledge of safety rules, equipment operation techniques, and practical maneuvering skills.

4. Obtain relevant worker safety certifications: For example, OSHA 10-hour or 30-hour safety training may be required before or alongside licensing.

5. Apply for a license or certification card: After fulfilling training and examination requirements, operators can apply to regulatory bodies to receive an official license or operator card.

Licensing requirements and processes vary widely, so verifying regional mandates and consulting professional bodies beforehand is critical.

Purchasing a used excavator can save costs but requires careful assessment to ensure long-term reliability and compliance.

- Inspect Hydraulic Systems and Engine Health: Look for leaks, unusual noises, or smoke emissions. These components are costly to repair.

- Check Structural Integrity: Examine the boom, arm, bucket, and tracks for cracks, dents, or wear. Structural damage compromises safety and functionality.

- Review Maintenance Logs and Usage History: Consistent maintenance records indicate a well-cared-for machine, while gaps or omissions suggest possible neglect.

- Confirm Seller's Credibility: Buy from reputable dealers or verified sources to mitigate risk of fraud or hidden defects.

- Consider Warranties or Purchase After-sales Support: Some sellers provide limited warranties or post-sale support, which adds value and security.

- Perform Daily Pre-operation Checks: Inspect fluid levels, controls, and safety features before each use to catch potential issues early.

- Follow Manufacturer's User Manual Strictly: Each excavator model may have unique controls and maintenance recommendations.

- Use Personal Protective Equipment (PPE): Helmets, gloves, steel-toed boots, and reflective clothing protect operators and surrounding workers.

- Avoid Operating in Unsafe Weather or Unstable Ground Conditions: Wet or uneven terrains increase risks of tipping or mechanical failure.

- Attend Refresher Training Sessions Regularly: Even experienced operators benefit from periodic training to keep skills sharp and knowledge current.

By combining careful purchase planning with disciplined operating habits, users can maximize the value and safety of their used excavator.

In summary, whether or not you can use an excavator without a license depends largely on your location and the specific industry standards involved. However, possessing proper training or a license is highly advisable for safety, efficiency, and legal compliance. When working with a used excavator, be especially careful to confirm all legal and mechanical prerequisites are met. Prioritize your operator training and certification to ensure that you can handle the equipment safely and competently. Remember, investing in licensing and ongoing education ultimately protects both the operator and the equipment, contributing to successful project outcomes.

Generally, licensing may not be mandated on private property depending on your region's laws. However, training and certification are still highly recommended for safety and insurance purposes.

Most rental companies require proof of licensure or certification before renting an excavator due to liability and insurance policies, even for used machines.

A license is issued by a governmental authority permitting legal operation, while certification is often provided by private organizations to validate skills and training. Both are important but serve distinct regulatory and professional purposes.

License renewal periods vary by jurisdiction, commonly every 1 to 5 years, often requiring refresher training or reexaminations.

Some regions allow operation of mini excavators without a full license but still require basic training and adherence to safety protocols to minimize risk.